Microwaved nanoribbons may bolster oil and gas wells

Wellbores drilled to extract oil and gas can be dramatically reinforced with a small amount of modified graphene nanoribbons added to a polymer and microwaved, according to Rice University researchers.

Rice University researchers have developed a method to treat composite materials of graphene nanoribbons and thermoset polymers with microwaves in a way that could dramatically reinforce wellbores for oil and gas production.

Nam Dong Kim/Rice University

The Rice labs of chemist James Tour and civil and environmental engineer Rouzbeh Shahsavari combined the nanoribbons with an oil-based thermoset polymer intended to make wells more stable and cut production costs. When cured in place with low-power microwaves emanating from the drill assembly, the composite would plug the microscopic fractures that allow drilling fluid to seep through and destabilize the walls.

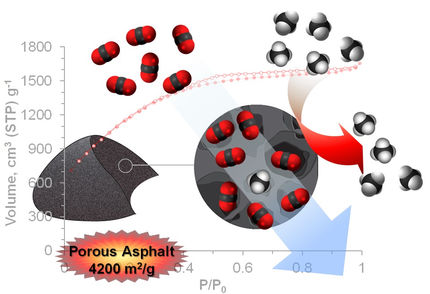

The researchers said that in the past, drillers have tried to plug fractures with mica, calcium carbonate, gilsonite and asphalt to little avail because the particles are too large and the method is not efficient enough to stabilize the wellbore.

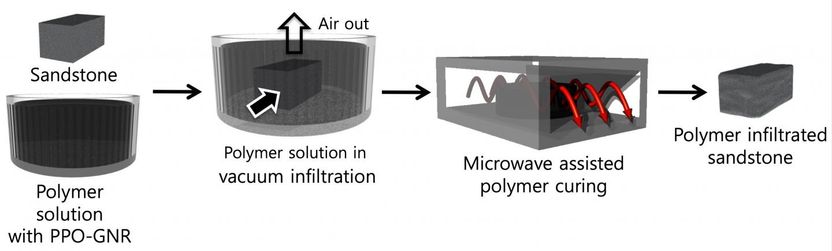

In lab tests, a polymer-nanoribbon mixture was placed on a sandstone block, similar to the rock that is encountered in many wells. The team found that rapidly heating the graphene nanoribbons to more than 200 degrees Celsius with a 30-watt microwave was enough to cause crosslinking in the polymer that had infiltrated the sandstone, Tour said. The microwave energy needed is just a fraction of that typically used by a kitchen appliance, he said.

"This is a far more practical and cost-effective way to increase the stability of a well over a long period," Tour said.

In the lab, the nanoribbons were functionalized -- or modified -- with polypropylene oxide to aid their dispersal in the polymer. Mechanical tests on composite-reinforced sandstone showed the process increased its average strength from 5.8 to 13.3 megapascals, a 130 percent boost in this measurement of internal pressure, Shahsavari said. Similarly, the toughness of the composite increased by a factor of six.

"That indicates the composite can absorb about six times more energy before failure," he said. "Mechanical testing at smaller scales via nanoindentation exhibited even more local enhancement, mainly due to the strong interaction between nanoribbons and the polymer. This, combined with the filling effect of the nanoribbon-polymer into the pore spaces of the sandstone, led to the observed enhancements."

The researchers suggested a low-power microwave attachment on the drill head would allow for in-well curing of the nanoribbon-polymer solution.

Original publication

Nam Dong Kim, Andrew Metzger, Vahid Hejazi, Yilun Li, Anton Kovalchuk, Seoung-Ki Lee, Ruquan Ye, Jason A. Mann, Carter Kittrell, Rouzbeh Shahsavari, and James M. Tour; "Microwave Heating of Functionalized Graphene Nanoribbons in Thermoset Polymers for Wellbore Reinforcement"; ACS Applied Materials & Interfaces; 2016

Original publication

Nam Dong Kim, Andrew Metzger, Vahid Hejazi, Yilun Li, Anton Kovalchuk, Seoung-Ki Lee, Ruquan Ye, Jason A. Mann, Carter Kittrell, Rouzbeh Shahsavari, and James M. Tour; "Microwave Heating of Functionalized Graphene Nanoribbons in Thermoset Polymers for Wellbore Reinforcement"; ACS Applied Materials & Interfaces; 2016

Topics

Organizations

Other news from the department science

Get the chemical industry in your inbox

By submitting this form you agree that LUMITOS AG will send you the newsletter(s) selected above by email. Your data will not be passed on to third parties. Your data will be stored and processed in accordance with our data protection regulations. LUMITOS may contact you by email for the purpose of advertising or market and opinion surveys. You can revoke your consent at any time without giving reasons to LUMITOS AG, Ernst-Augustin-Str. 2, 12489 Berlin, Germany or by e-mail at revoke@lumitos.com with effect for the future. In addition, each email contains a link to unsubscribe from the corresponding newsletter.

Most read news

More news from our other portals

Last viewed contents

Brookfield AMETEK, Inc. - Middleboro, USA

JPK BioAFM - Bruker Nano GmbH - Berlin, Germany

Balcke-Dürr GmbH - Düsseldorf, Germany

Frost & Sullivan Examines the Opportunities in the Sub-Saharan African Chemicals Industry

DyStar Colours Distribution GmbH - Raunheim, Germany

AllocNow GmbH - Bonn, Germany

ComputerBV GmbH - Frankenthal, Germany

Nagarjuna Spawnt GmbH - Bitterfeld, Germany

Pixargus GmbH - Aachen, Germany

Bartels Mikrotechnik GmbH - Dortmund, Germany

MOLLET Füllstandtechnik GmbH - Osterburken, Germany