Recyclable, sugar-derived foam - a renewable alternative to traditional polyurethanes?

polyurethanes in products from cushy sofas to stretchy spandex have made sitting, sleeping and walking more comfortable. But once they have served their purpose, most of the non-degradable materials pile up in landfills. Now scientists report a potential way to reduce future waste: a chemically recyclable foam made using a new sugar-derived material.

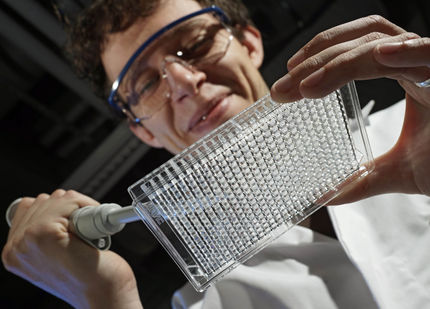

Polyurethanes are highly versatile materials. In addition to furniture and clothing, manufactures use them in electronics, cars, floors and medical devices. But the materials come from petroleum, and efforts to recycle them are limited. To tackle the huge amount of waste this creates, scientists are pursuing more sustainable options. Marc A. Hillmyer and colleagues developed an efficient method to make a sugar-derived rubbery polyester compound called poly(β-methyl-δ-valerolactone), or PMVL, that can be used in new chemically-recyclable polyurethanes.

Using this new polymer, the researchers made flexible polyurethane foams that were comparable in performance to commercial analogs. To test whether the foams could be recycled, the team first added a catalyst, then heated the materials to a high temperature. Through this process, the researchers recovered up to 97 percent of the starting β-methyl-δ-valerolactone (MVL) monomer in high purity. The researchers then used what they recovered to re-make PMVL with essentially identical properties.

Original publication

Most read news

Original publication

Deborah K. Schneiderman, Marie E. Vanderlaan, Alexander M. Mannion, Tessie R. Panthani, Derek C. Batiste, Jay Z. Wang, Frank S. Bates, Christopher W. Macosko, and Marc A. Hillmyer; "Chemically Recyclable Biobased Polyurethanes"; ACS Macro Letters; 2016

Organizations

Other news from the department science

Get the chemical industry in your inbox

By submitting this form you agree that LUMITOS AG will send you the newsletter(s) selected above by email. Your data will not be passed on to third parties. Your data will be stored and processed in accordance with our data protection regulations. LUMITOS may contact you by email for the purpose of advertising or market and opinion surveys. You can revoke your consent at any time without giving reasons to LUMITOS AG, Ernst-Augustin-Str. 2, 12489 Berlin, Germany or by e-mail at revoke@lumitos.com with effect for the future. In addition, each email contains a link to unsubscribe from the corresponding newsletter.