Researchers move one step closer to sustainable hydrogen production

Splitting water into its hydrogen and oxygen parts may sound like science fiction, but it's the end goal of chemists and chemical engineers like Christopher Murray of the University of Pennsylvania and Matteo Cargnello of Stanford University.

They work in a field called photocatalysis, which, at its most basic, uses light to speed up chemical reactions. They've come a step closer to such a feat by tailoring the structure of a material called titania, one of the best-known photocatalysts, to hasten hydrogen production from biomass-derived compounds.

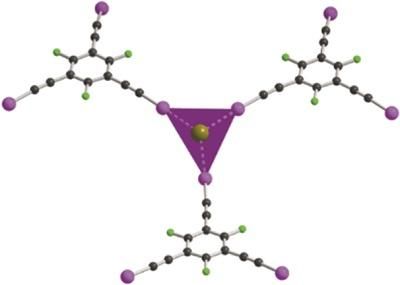

Through a five-year collaboration with Drexel University, the University of Trieste in Italy, the University of Cadiz in Spain and the Leibniz Institute for Catalysis in Germany, the researchers determined that lengthening nanorods to 50 nanometers, a size 1,000 times smaller than the diameter of a hair, increased the hydrogen production rate of a rare form of titania called brookite, only accessible at the nanoscale.

Using this unique crystal structure and controlling the nanorod dimensions offer new avenues for engineering the material's activity, and, because the process is theoretically simple to replicate, even at a large scale, it could have real implications for the future of clean energy and sustainable hydrogen production.

The researchers published their results in the journal Proceedings of the National Academy of Sciences.

"These insights are one more piece in an important puzzle as we work to harness the phenomena exhibited by Earth's materials," said Murray, a Penn Integrates Knowledge Professor and the Richard Perry University Professor of Chemistry and Materials Science and Engineering.

One such material comes from the sun. "One idea behind photocatalysis is, what if we could make hydrogen using sunlight from abundant compounds? We wouldn't have to produce it from fossil fuels, which has global warming effects," said Cargnello, a former Penn postdoc who is now a Stanford assistant professor of chemical engineering.

"If we could get that hydrogen from a renewable source, then the entire process would be totally sustainable" said Paolo Fornasiero, a University of Trieste professor of chemical and pharmaceutical sciences who collaborated with the Murray team on hydrogen measurements.

On its face, the process sounds straightforward: Titania absorbs sunlight, which initiates a chemical reaction that generates hydrogen. But the vehicles responsible for this response, called electrons and holes, tend to jump the gun, reacting with each other almost immediately due to their opposite charges.

They also execute different functions, with the negatively charged electrons carrying out reductions, and the positively charged holes performing oxidations. "What you want is that electron to reduce the water to hydrogen and that hole to oxidize the water to oxygen, such that the combination of these two half-reactions produces hydrogen gas on one side and oxygen gas on the other," Cargnello said.

To attempt to stop the electrons and holes from reacting too soon, the research team put space between them using nanorods sized precisely from 15 to 50 nanometers, eventually determining that the longest rod resulted in the best activity. Though the experiment parameters didn't allow them to build beyond 50 nanometers, the scientists had essentially forced the electrons and holes to react with water rather than each other.

Cargnello said what they've learned can be a playbook for others in the field. "If you want to have more efficient photocatalysts," he said, "make elongated structures to create these highways for electrons to escape from holes and react much faster with the molecules."

This team isn't the first to attempt such an experiment with titania, according to Murray, who has appointments in the School of Arts & Sciences and the School of Engineering and Applied Science. "Titania is Earth-abundant and non-toxic, highly desirable as a material for solar-energy conversion," he said. "Many researchers are working to improve the efficiency with which it uses the solar spectrum."

Murray's team opted to use solution-phase chemistry, a bottom-up approach, instead of a process many others employ called fabrication, which is top-down.

"With fabricated structures, you take a big chunk and cut it down into smaller and smaller features," Cargnello said. "There is a limit to how small these structures can be, however, and the production is not scalable. In the Murray lab, we added one atom to another to make the nanorods, with precise control at the nanoscale and potential scalability." Jason Baxter's team at Drexel explored the photo-dynamics of these systems.

Though the chemical process gets much more exact, it hasn't yet lead Murray's team to that dream of splitting pure water. To date, the scientists have employed biomass-derived compounds such as alcohols, breaking them down into hydrogen and carbon dioxide.

That this generates CO2 may be counter to the clean-energy ideal, but Cargnello has an answer to this concern: Plants will absorb and turn the otherwise-discarded CO2 into additional biomass. "This would give us a close to carbon-neutral cycle," he said. Right now, that's precisely what's happening. "The nanorods take the light and the biomass-derived compound and transform them into hydrogen and CO2."

Hydrogen has shown great promise as an emission-free alternative fuel when not made from natural gas. One challenge to wide acceptance, though, is the low cost and convenience of fossil fuels. That could change with the discovery of more efficient materials capable of producing hydrogen from sunlight and abundant compounds at higher rates.

Then "we may be more competitive with hydrogen production from fossil fuels," Cargnello said. "Our work is one step in that direction."