Biodiesel from sugarcane more economical than soybean

Advertisement

America's oil consumption far exceeds that of every other country in the world. What's more, it's unsustainable. Therefore, in 2007, Congress mandated a move away from petroleum-based oils toward more renewable sources. soybeans, an important dietary protein and the current primary source of plant-based oils used for biodiesel production, only yield about one barrel per acre. At this rate, the soybean crop could never quench the nation's thirst for oil.

Researchers have engineered a way to convert sugar into oil in sugarcane, resulting in a new and sustainable biodiesel source.

S.P. Long

To address this issue, the Department of Energy's Advanced Research Projects Agency-Energy (ARPA-E) program called for high-risk, high-reward projects that could develop new drop-in fuels in its PETRO program. A team led by University of Illinois researchers answered the call by imagining and successfully achieving a way to produce large quantities of oil from sugarcane. Their most recent study demonstrates the economic benefits of this technology relative to soybean oil.

"We thought that if we could go back to the drawing board, we'd need a very productive crop. And we would also need something that could grow on land that isn't being used intensively for food. We came up with sugarcane and sweet sorghum," recalls Stephen P. Long, U of I crop scientist and lead investigator on the project.

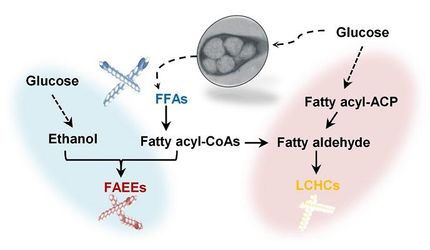

The team altered sugarcane metabolism to convert sugars into lipids, or oils, which could be used to produce biodiesel. The natural makeup of sugarcane is typically only about 0.05 percent oil. Within a year of starting the project, the team was able to boost oil production 20 times, to approximately 1 percent. At the time of this writing, the so-called "oil-cane" plants are producing 12 percent oil. The ultimate goal is to achieve 20 percent. Oil cane has additional advantages that have been engineered by the team. These include increased cold tolerance and more efficient photosynthesis, which leads to greater biomass production and even more oil.

"If all of the energy that goes into producing sugar instead goes into oil, then you could get 17 to 20 barrels of oil per acre," Long explains. "A crop like this could be producing biodiesel at a very competitive price, and could represent a perpetual source of oil and a very significant offset to greenhouse gas emissions, as well."

In their analysis, the team looked at the land area, technology, and costs required for processing oil-cane biomass into biodiesel under a variety of oil production scenarios, from 2 percent oil in the plant to 20 percent. These numbers were compared with normal sugarcane, which can be used to produce ethanol, and soybean.

An advantage of oil cane is that leftover sugars in the plant can be converted to ethanol, providing two fuel sources in one.

"Modern sugarcane mills in Brazil shared with us all of their information on energy inputs, costs, and machinery. Then we looked at the U.S. corn ethanol industry, and how they separated the corn oil. Everything we used is existing technology, so that gave us a lot of security on our estimates," Long says.

The analysis showed that oil cane with 20 percent oil in the stem, grown on under-utilized acres in the southeastern United States, could replace more than two-thirds of the country's use of diesel and jet fuel. This represents a much greater proportion than could be supplied by soybean, even if the entire crop went to biodiesel production. Furthermore, oil cane could achieve this level of productivity on a fraction of the land area that would be needed for crops like soybean and canola, and it could do so on land considered unusable for food crop production.

The current full production cost of biodiesel from soybean is $4.10 per gallon ($1.08 per liter). Using oil cane instead, that cost decreases to $3.30 per gallon for 2 percent oil cane and to $2.20 per gallon for 20 percent oil cane. The ethanol produced from 1-, 5- and 10 percent oil cane would add to the cost benefit.

Although $2.20 per gallon does not represent a large savings over the current price of gasoline in the United States, Long cautions consumers and politicians to look at the bigger picture.

"We know from our past experience that it's not going to last," he says. "We need to start building for a future when gas is no longer as low as $1.50 per gallon, and we need to avoid any future dependency on other countries for our oil. We are lucky to have the land resources to do this and, in doing so, to ensure that future generations have a supply of oil that is domestic and renewable."