Carbon dioxide in ever wider use as a raw material

Covestro and partners working on new climate-friendly process

Advertisement

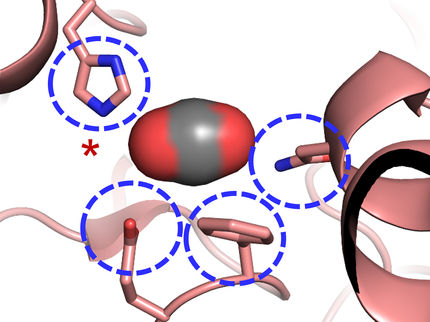

carbon dioxide is being used ever more widely as a novel raw material in plastics production. As part of the “Production Dreams” project, materials manufacturer Covestro is working with RWTH Aachen University and the Technical University of Berlin, both in Germany, on a further process that will enable the greenhouse gas to be used as well in the environmentally friendly manufacture of elastomers on an industrial scale. Elastomers are plastics that hold their shape but are elastically formable.

The German Federal Ministry of Education and Research (BMBF) is providing funding for the project of up to EUR 1.5 million over the next three years as part of the “r+Impuls – Impulse für industrielle Ressourceneffizienz” (r+Impulse –impetus for industrial resource efficiency) measure under the “Research for Sustainable Development” (FONA³) framework program.

Around 25% of oil can be replaced with CO2

Elastomers are normally made entirely from petroleum. Now, some 25 percent of the oil used to manufacture a precursor can be replaced with CO2. The resulting polyether carbonate polyurethane can be processed into elastomers.

Individual batches of the innovative material have already been manufactured in the lab. The focus is now on developing a continuous process that will support cost-effective production on an industrial scale.

“By participating in the BMBF Production Dreams collaboration, we are redoubling our efforts to develop cost-effective and climate-friendly production processes that use CO2 as an element in high-performance plastics,” says project manager Dr. Jochen Norwig, who works in catalysis research at Covestro in Leverkusen.

Significantly better ecological credentials

Small-scale tests have so far shown that elastomers manufactured using this process exhibit the same impressive qualities as those produced using only petrochemical raw materials. At the same time, the new process that the project partners want to develop and put into practice is much more energy-efficient and uses a much lower quantity of solvents. It therefore has significantly better ecological credentials than conventional processes. Using less petroleum also means fewer processing steps have to be carried out before it can be used in the elastomer, which in turn reduces the overall CO2 emissions and energy consumption associated with the process.

Using carbon dioxide thus conserves petroleum, which is a finite resource, and expands the base of raw materials used in the chemical and plastics industries. The number of plastics that can be produced using CO2 is also growing.

Thanks to research carried out by Covestro and its partners, carbon dioxide can already be used in the production of polyurethane flexible foam. Covestro is aiming to open the first production facility this year at the Dormagen site, where it will manufacture a polyol with a 20 percent CO2 content as a precursor. This precursor will be used primarily in flexible foam applications such as upholstery and mattresses.

Most read news

Organizations

Other news from the department science

Get the chemical industry in your inbox

By submitting this form you agree that LUMITOS AG will send you the newsletter(s) selected above by email. Your data will not be passed on to third parties. Your data will be stored and processed in accordance with our data protection regulations. LUMITOS may contact you by email for the purpose of advertising or market and opinion surveys. You can revoke your consent at any time without giving reasons to LUMITOS AG, Ernst-Augustin-Str. 2, 12489 Berlin, Germany or by e-mail at revoke@lumitos.com with effect for the future. In addition, each email contains a link to unsubscribe from the corresponding newsletter.