Fraunhofer LBF investigates recycling of halogen-free flame retardant

Zero plastics to landfill increases the need to mechanical recycling of plastics. This also applies to flame retardant plastics which are increasingly formulated with halogen-free flame retardants. According to EU regulations, plastic waste recycling is to increase in quality, and recycling rates should continue to rise: the EU target for 2020 is 70 percent.

The Fraunhofer Institute for Structural Durability and System Reliability LBF in Darmstadt/Germany has therefore launched a new research project on the recycling of halogen-free flame retardant plastics. For the first time, the project will provide answers to the recyclability of halogen-free flame retardant plastics.

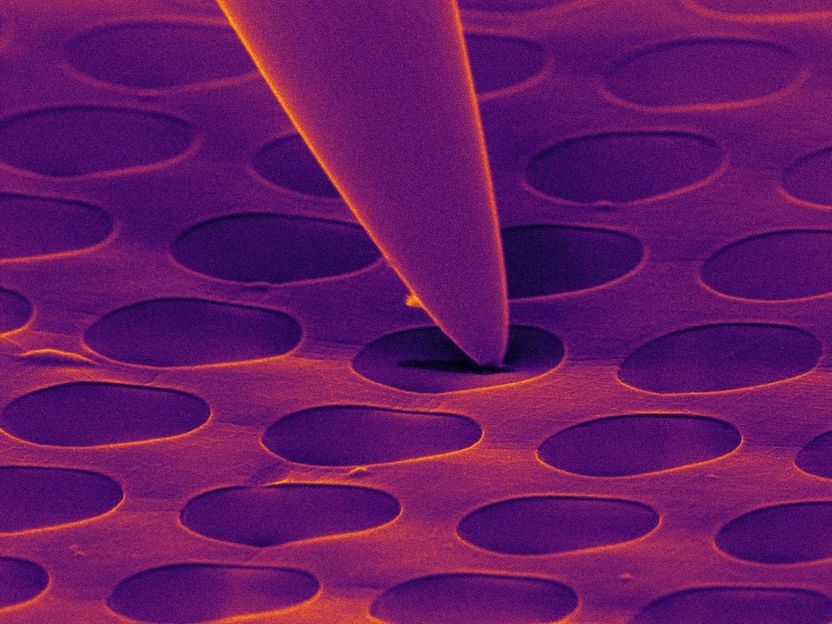

Fraunhofer LBF investigates recycling of halogen-free flame retardant plastics in a new research project.

Fraunhofer LBF

In Europe, around 70 percent halogen-free PIN flame retardants based on phosphorus (P), inorganic substances (I) and nitrogen (N) are already in use. Their share will grow as they meet the requirement of many users for good environmental compatibility, cost efficiency and reliable flame proofing in the final application. So far very little is known about the mechanical recycling of these plastics although, with an estimated value of three billion euros, they are very important economically in the European market. This concerns mainly the electrical and electronics industry, construction and transportation. The results of the project are significant for polymer, flame retardant and additive manufacturers, compounders, masterbatch producers, producers of plastic parts, recycling companies and consulting firms.

Ensuring recyclability

For the first time, the new multi-year research project of the Fraunhofer LBF will provide answers to the recyclability of halogen-free flame retardant plastics and suggest ways to ensure recyclability. At the same time it will make an important contribution to the socio-political issues of resource efficiency and security. The research will be carried out as part of the project funding Industrial Community Research of the AiF (German Federation of Industrial Research Associations, here Forschungsgesellschaft Kunststoffe e.V., www.fgkunststoffe.de) and with the participation of member companies of PINFA. PINFA (Phosphorus, Inorganic & Nitrogen Flame Retardants Association, www.pinfa.org) represents manufacturers and users of halogen-free flame retardants and is part of the European Chemical Industry Council (Cefic).

The companies concerned will benefit from the new research project in many ways. They will be better able to use their own product waste in the case of flame-retardant formulations and to save costs. The findings will lead to enhanced quality products with high safety standards, potential hazards of degradation products will be identified and can be eliminated. Competitive advantages will continue to exist for using recycled plastics as a marketing tool and for constructing new products based on them.

Companies will be able to implement results immediately

As the institute draws on application-relevant and current commercial formulations, interested companies will be able to implement the findings immediately and directly. The ability to reuse production waste using the knowledge gained will generate a definite competitive edge. When using recyclates, it will be possible to minimize risks such as product liability based on the data compiled.

Due to the targeted mechanical recovery of recycled halogen-free plastics, the research project will reduce the use of raw materials and contribute to conserving and using resources more efficiently. Thanks to the improved properties of recycled plastics, such as the mechanical characteristics, it will be possible to open up new applications for these recyclates and build up new business areas. With a market volume in Europe of three billion euros for halogen-free flame-retardant plastics, the Fraunhofer LBF estimates the potential cost saving due to using production waste at 150 million euros per year. The potential value for used plastics is significantly higher.

Recycling additives play an important part in quality improvement in the mechanical recycling of plastics. With the addition of customized stabilizers, compatibilizers and reactive additives, recycled materials achieve qualities that can compete with those of new material. The number of recyclate additives has increased considerably in recent years. The difficulty arising from this for producers is how to develop the best solution technically and economically for the desired property profile. This is where the Fraunhofer LBF with its plastics division is available as a neutral partner that is continuously extending its knowledge of recyclates.

Other news from the department science

Get the chemical industry in your inbox

By submitting this form you agree that LUMITOS AG will send you the newsletter(s) selected above by email. Your data will not be passed on to third parties. Your data will be stored and processed in accordance with our data protection regulations. LUMITOS may contact you by email for the purpose of advertising or market and opinion surveys. You can revoke your consent at any time without giving reasons to LUMITOS AG, Ernst-Augustin-Str. 2, 12489 Berlin, Germany or by e-mail at revoke@lumitos.com with effect for the future. In addition, each email contains a link to unsubscribe from the corresponding newsletter.

Most read news

More news from our other portals

Last viewed contents

Asesoría y Proveedora de Equipos para Laboratorio, S.A. de C.V. (Aspelab) - Mexiko, Mexico

New class of materials could revolutionize biomedical, alternative energy industries

Messer topping-out ceremony for second production facility in Germany

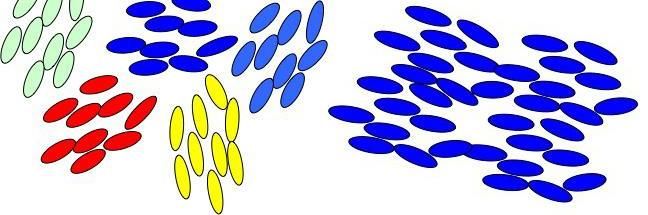

How order first appears in liquid crystals