A nanoscale look at why a new alloy is amazingly tough

Just in time for the icy grip of winter: A team of researchers led by scientists from the Lawrence Berkeley National Laboratory (Berkeley Lab) has identified several mechanisms that make a new, cold-loving material one of the toughest metallic alloys ever.

The alloy is made of chromium, manganese, iron, cobalt and nickel, so scientists call it CrMnFeCoNi. It's exceptionally tough and strong at room temperature, which translates into excellent ductility, tensile strength, and resistance to fracture. And unlike most materials, the alloy becomes tougher and stronger the colder it gets, making it an intriguing possibility for use in cryogenic applications such as storage tanks for liquefied natural gas.

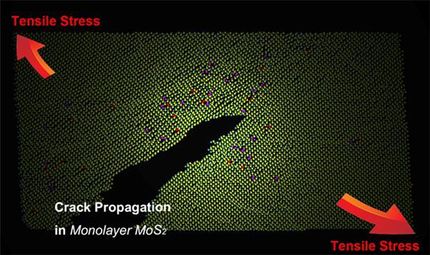

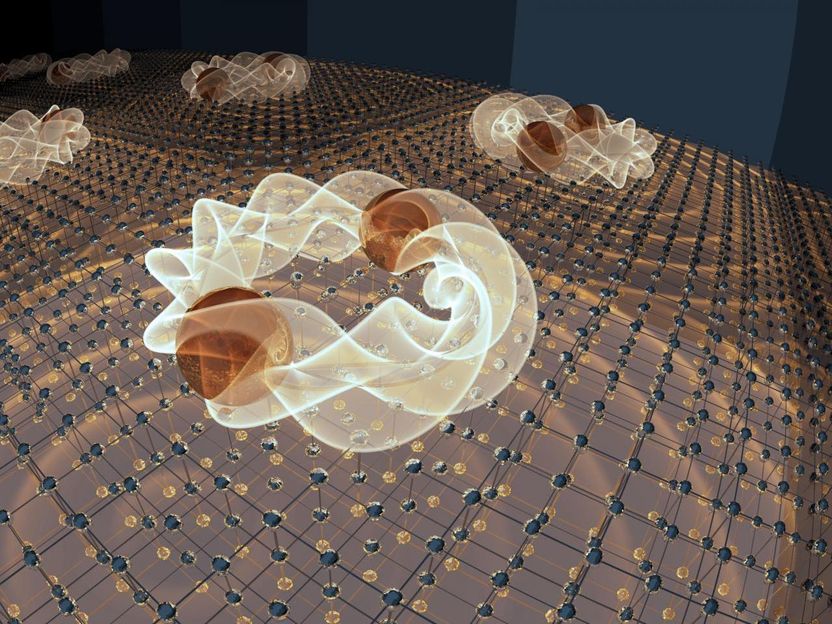

To learn its secrets, the Berkeley Lab-led team studied the alloy with transmission electron microscopy as it was subjected to strain. The images revealed several nanoscale mechanisms that activate in the alloy, one after another, which together resist the spread of damage. Among the mechanisms are bridges that form across cracks to inhibit their propagation. Such crack bridging is a common toughening mechanism in composites and ceramics but not often seen in unreinforced metals.

Their findings could guide future research aimed at designing metallic materials with unmatched damage tolerance.

"We analyzed the alloy in earlier work and found spectacular properties: high toughness and strength, which are usually mutually exclusive in a material," says Robert Ritchie, a scientist with Berkeley Lab's Materials Sciences Division who led the research with Qian Yu of China's Zhejiang University and several other scientists.

"So in this research, we used TEM to study the alloy at the nanoscale to see what's going on," says Ritchie.

In materials science, toughness is a material's resistance to fracture, while strength is a material's resistance to deformation. It's very rare for a material to be both highly tough and strong, but CrMnFeCoNi isn't a run-of-the-mill alloy. It's a star member of a new class of alloys developed about a decade ago that contains five or more elements in roughly equal amounts. In contrast, most conventional alloys have one dominant element. These new multi-component alloys are called high-entropy alloys because they consist primarily of a simple solid solution phase, and therefore have a high entropy of mixing.

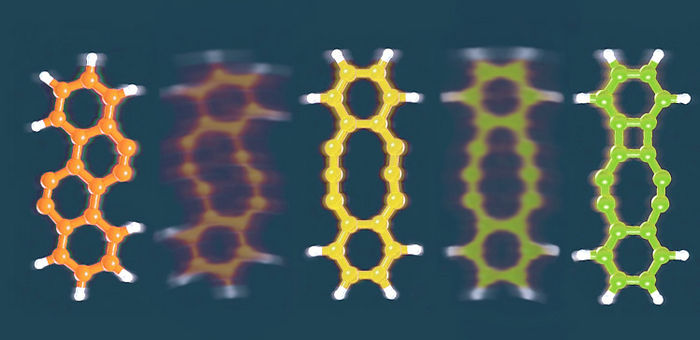

They're a hot topic in materials research, and have only recently been available in a quality suitable for study. In 2014, Ritchie and colleagues found that at very cold temperatures, when CrMnFeCoNi deforms, a phenomenon called "twinning" occurs, in which adjacent crystalline regions form mirror arrangements of one another. Twinning likely plays a part in the alloy's incredible toughness and strength. But twinning isn't extensively found in the alloy at room temperature (except in the crack bridges), yet the alloy's toughness and strength is still almost off the charts.

"If we don't see twinning at room temperature, then what other mechanisms give the alloy these amazing properties?" asks Ritchie.

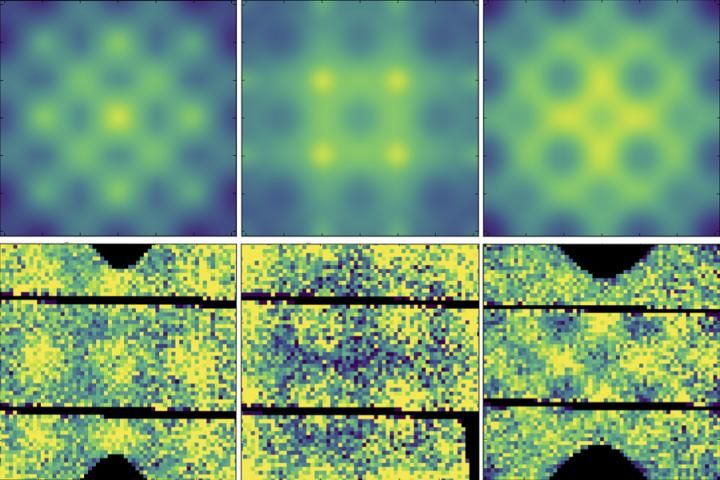

To find out, the scientists subjected the alloy to several straining experiments at room temperature, and used transmission electron microscopy to observe what happens.

Their time-lapse images revealed two phenomena related to shear stress: slow-moving perfect dislocations that give the material strength, and fast-moving partial dislocations that enhance ductility. They also saw a phenomenon involving partial dislocations called "three-dimensional stacking fault defects," in which the 3-D arrangement of atoms in a region changes. These faults are big barriers to dislocation, like placing a stack of bricks in front of a growing fissure, and serve to harden the alloy.

The images also captured the nanoscale version of chewing a mouthful of toffee and having your teeth stick together: In some cases, tiny bridges deformed by twinning are generated across a crack, which help prevent the crack from growing wider.

"These bridges are common in reinforced ceramics and composites," says Ritchie. "Our research found that all of these nanoscale mechanisms work together to give the alloy its toughness and strength."

Original publication

Other news from the department science

Get the chemical industry in your inbox

By submitting this form you agree that LUMITOS AG will send you the newsletter(s) selected above by email. Your data will not be passed on to third parties. Your data will be stored and processed in accordance with our data protection regulations. LUMITOS may contact you by email for the purpose of advertising or market and opinion surveys. You can revoke your consent at any time without giving reasons to LUMITOS AG, Ernst-Augustin-Str. 2, 12489 Berlin, Germany or by e-mail at revoke@lumitos.com with effect for the future. In addition, each email contains a link to unsubscribe from the corresponding newsletter.

Most read news

More news from our other portals

Last viewed contents

How water helps the substrate into the enzyme - When water is present in tiny quantities it develops special properties

Neutrinos weighed by the world's most precise scale

Breaking bad metals with neutrons

Analytica and ceramitec 2024 in parallel - Added value for exhibitors and visitors

Tip tricks control reactions in a single molecule - Pulses from an atom-sharp tip enable researchers to break and form chemical bonds at will

Advances in the logistics of liquid goods - Self-loading of road tankers by the driver

A different spin on superconductivity - Unusual particle interactions open up new possibilities in exotic materials

With carbon nanotubes, a path to flexible, low-cost sensors - Potential applications range from air-quality monitors to electronic skin

ISO toughens toy safety for hazard-free and fun play

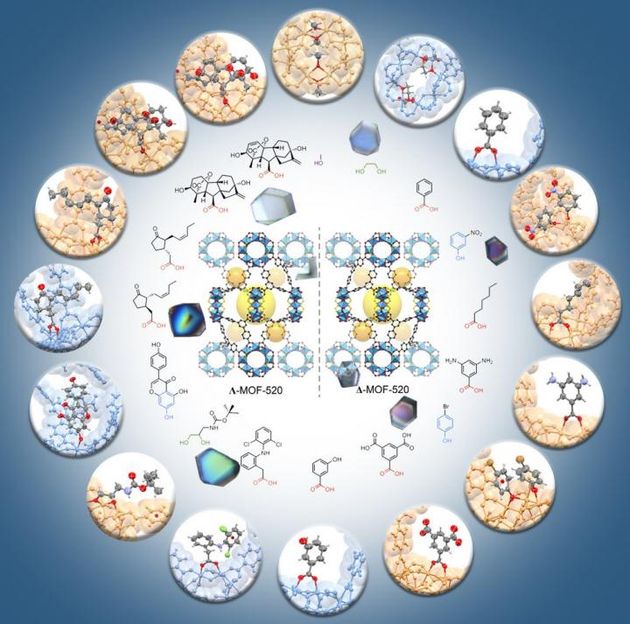

A new way to display the 3-D structure of molecules