Superhydrophobic coating protects without the price

A new class of superhydrophobic nanomaterials might simplify the process of protecting surfaces from water

A material made by scientists at Rice University, the University of Swansea, the University of Bristol and the University of Nice Sophia Antipolis is inexpensive, nontoxic and can be applied to a variety of surfaces via spray- or spin-coating. The hydrocarbon-based material may be a "green" replacement for costly, hazardous fluorocarbons commonly used for superhydrophobic applications, Rice chemist Andrew Barron said.

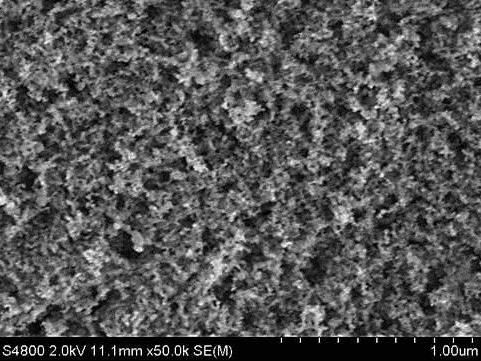

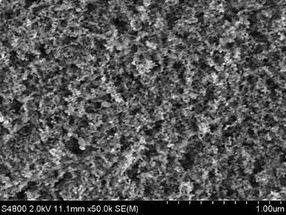

A scanning electron microscope image of a new superhydrophobic material shows the rough surface of functionalized alumina nanoparticles. Scientists at Rice University and the University of Swansea led the creation of the environmentally friendly material.

University of Swansea

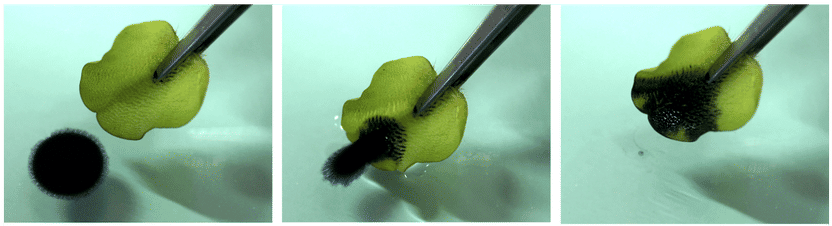

An environmentally friendly superhydrophobic coating repels water as effectively as commercial coatings that employ hazardous materials, according to scientists at Rice University and the University of Swansea.

Shirin Alexander/University of Swansea

"Nature knows how to make these materials and stay environmentally friendly," Barron said. "Our job has been to figure out how and why, and to emulate that." The lotus leaf was very much on their minds as the researchers tried to mimic one of the most hydrophobic -- water-repelling -- surfaces on the planet. Barron said the leaf's abilities spring from its hierarchy of microscopic and nanoscale double structures.

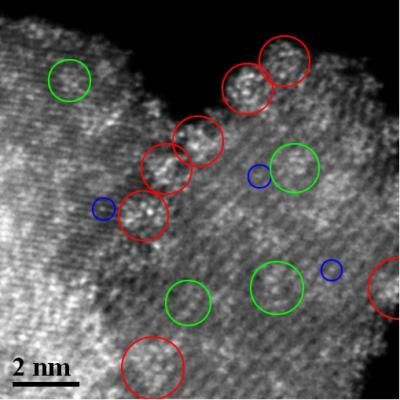

"In the lotus leaf, these are due to papillae within the epidermis and epicuticular waxes on top," he said. "In our material, there is a microstructure created by the agglomeration of alumina nanoparticles mimicking the papillae and the hyperbranched organic moieties simulating the effect of the epicuticular waxes."

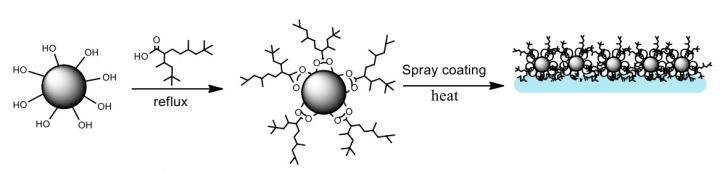

Fabrication and testing of what the researchers call a branched hydrocarbon low-surface energy material (LSEM) were carried out by lead author Shirin Alexander, a research officer at the Energy Safety Research Institute at the Swansea University Bay Campus.

There, Alexander coated easily synthesized aluminum oxide nanoparticles with modified carboxylic acids that feature highly branched hydrocarbon chains. These spiky chains are the first line of defense against water, making the surface rough. This roughness, a characteristic of hydrophobic materials, traps a layer of air and minimizes contact between the surface and water droplets, which allows them to slide off.

To be superhydrophobic, a material has to have a water contact angle larger than 150 degrees. Contact angle is the angle at which the surface of the water meets the surface of the material. The greater the beading, the higher the angle. An angle of 0 degrees is basically a puddle, while a maximum angle of 180 degrees defines a sphere just touching the surface.

The Barron team's LSEM, with an observed angle of about 155 degrees, is essentially equivalent to the best fluorocarbon-based superhydrophobic coatings, Barron said. Even with varied coating techniques and curing temperatures, the material retained its qualities, the researchers reported.

Potential applications include friction-reducing coatings for marine applications where there is international agreement in trying to keep water safe from such potentially dangerous additives as fluorocarbons, Barron said. "The textured surfaces of other superhydrophobic coatings are often damaged and thus reduce the hydrophobic nature," he said. "Our material has a more random hierarchical structure that can sustain damage and maintain its effects."

He said the team is working to improve the material's adhesion to various substrates, as well as looking at large-scale application to surfaces.