New facility will test how long nuclear reactor components last

McMaster University nuclear safety expert John Luxat's aim is to create a legacy of advanced nuclear research capability in a regional research facility in Hamilton, Ont., called the Centre for Advanced Nuclear Systems (CANS).

It's taken six years of planning and $24.5 million from the Canada Foundation for Innovation, the Ontario Ministry of Research and Innovation and private donations, but the engineering physics professor's dream to open a network of five facilities dedicated to the study of nuclear systems is about to be realized in early 2016.

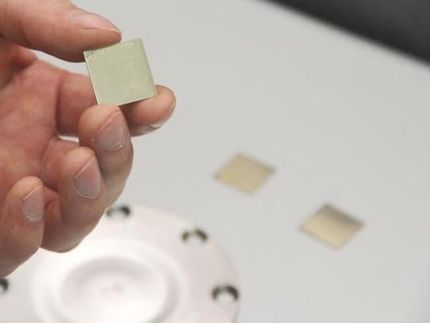

The goal, says Luxat, is to better understand the lifespan of components in nuclear reactors when subjected to intense neutron irradiation, essentially how materials change and degrade over time. The facility network will also provide lab support to the nuclear sector, particularly Ontario's three nuclear power plants: Bruce, Pickering and Darlington.

"If we understand these processes better we can extend operational life between expensive refurbishments," says Luxat. His research focuses on nuclear safety analysis and risk analysis, particularly severe accidents such as those in Fukushima; looking at ways to reuse and reprocess spent nuclear fuel to reduce nuclear waste; and thermal-mechanical behavior of nuclear components and structures under extreme events.

The largest of the new CANS facilities - the Nuclear Materials Post Irradiation Examination Facility located in the McMaster Accelerator Laboratory - has occupied most of Luxat's attention over the past 6 years. This facility is the one with the nine-foot giant claws, or remote radioactive material manipulators, and the most complex and expensive at about $17 million.

Five shielded workstations, each consisting of a thick lead-infused glass shielding window and a pair of remote manipulators are provided for moving materials, such as zirconium alloy tubes used in operating nuclear reactors, and processing the material through the sophisticated scientific assembly line of receiving, machining and waste handling, sample preparation, mechanical testing and light microscopy areas.

The five lead-infused windows for the workstation alone cost almost $1.7 million. "It's unique in the world," Luxat says of the hot cells lab. "In terms of its size and capabilities, it's the only one at a university anywhere in the world."

Other hot cells facilities with such capabilities are found in national labs, such as Chalk River and Idaho National Laboratories in the U.S.A., but not at educational institutions.

The hot cells were custom designed by U.S. company Merrick and Company, based in Denver, Colorado, over a two year period and was completed in 2013.

Other parts of the centre include a nuclear thermal-hydraulic testing facility, a lab dedicated to studying material defects using Positron Annhilation Spectroscopy, Nuclear Materials Characterization Facility, which features a Three Dimensional Atom Probe located in the Brockhouse Institute for Materials Research adjacent to the Canadian Centre for Electron Microscopy and Health Physics Dose Response Facility located at the University of Ontario Institute of Technology (UOIT).

The atom probe is the first one to be located Canada, will enable scientists to build detailed 3D atomic-level images from tiny samples using lasers and computer imaging.

Most read news

Other news from the department science

Get the chemical industry in your inbox

By submitting this form you agree that LUMITOS AG will send you the newsletter(s) selected above by email. Your data will not be passed on to third parties. Your data will be stored and processed in accordance with our data protection regulations. LUMITOS may contact you by email for the purpose of advertising or market and opinion surveys. You can revoke your consent at any time without giving reasons to LUMITOS AG, Ernst-Augustin-Str. 2, 12489 Berlin, Germany or by e-mail at revoke@lumitos.com with effect for the future. In addition, each email contains a link to unsubscribe from the corresponding newsletter.

Most read news

More news from our other portals

Last viewed contents

Artkim Group - Istanbul, Turkey

PFAS can suppress white blood cell’s ability to destroy invaders