Dow and Plant Research International to Collaborate on Therapeutic Glycoprotein Production in Plants

The Dow Chemical Company and Plant Research International B.V. of Wageningen, The Netherlands, have agreed to join forces to speed development of therapeutic proteins with mammalian-like glycan structures in transgenic plants. Through their collaboration, the companies will work to expand the utility of plant-based production for pharmaceutical proteins.

"Dow is delighted to be working with Plant Research International, an innovative leader in glycoprotein optimization in transgenic plants," said Kurt Hoeprich, Director of Market Development for Dow Plant-Based Biopharmaceuticals. "By optimizing glycoprotein production in plants, we can greatly expand the applicability of this new production platform in the rapidly growing biopharmaceutical marketplace."

According to industry research by a financial analyst from U.S. Bancorp Piper Jaffray, Inc., approximately 100 therapeutic proteins are now in mid- to late-stage clinical development. Potential manufacturing capacity shortages are leading pharmaceutical companies to consider plant-based production techniques.

Dirk Bosch, group leader at Plant Research International explains: "We are very pleased with this excellent match of Dow?s proprietary expression technologies and biopharmaceutical protein processing expertise with Plant Research International?s proven, integrated R&D capabilities for biosynthetic pathway engineering and protein analysis. This agreement will accelerate scientific developments at our institute and will place us in a position to help generate additional technological breakthroughs relevant to therapeutic protein production. Dow is a major player, with complementary skills and networks which support our ambition to use our expertise to benefit the pharmaceutical industry."

The agreement calls for Dow and Plant Research International to share their intellectual property estates in the field of glycosylated protein production in transgenic plants. Dow will lead commercialization of this exclusive technology for the therapeutic protein contract manufacturing market. Earlier this year, Dow secured patents on technology to enable glycan production in plants, which it will make available under this agreement. The agreement also involves a multi-year collaborative research program focused on further optimizing protein glycosylation in transgenic plant systems.

Dow also has agreements in place with Epicyte Pharmaceutical Inc., a biopharmaceutical company focused on the discovery and development of therapeutics to treat inflammatory and infectious diseases, and Centocor, Inc., to produce monoclonal antibodies in transgenic plants. According to Hoeprich, "This group of strategic agreements aligns key technology leaders toward fulfilling the promise of plant-based approaches to drug substance supply. Beyond overcoming the well-reported capacity limitations in the biopharmaceutical industry, a plant-based approach also holds the potential to lower capital and operating costs."

BACKGROUND

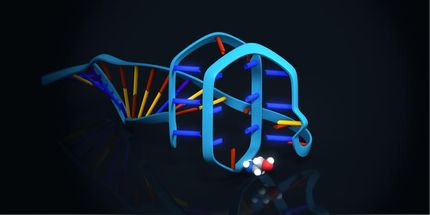

Glycans are a series of specific sugar units which are an integral part of many complex proteins, including many life-saving, high-value therapeutic proteins on the market today and in clinical development. The presence of glycans on proteins is essential for full functionality in the body and, more specifically, in the bloodstream. Many commercially important proteins must contain specific glycans to be fully functional or efficacious and work safely in the human body.

Examples of glycosylated therapeutic proteins include Factor VIII, a protein critical to the blood clotting process. Individuals with hemophilia are unable to produce Factor VIII protein and must administer the glycan-containing version of this protein on a regular basis. Further, 10 of the 11 monoclonal antibody drugs on the market today contain glycan structures. The presence of a glycan on an antibody therapeutic is critical for ensuring structural integrity is maintained and for optimum efficacy.

There are differences between glycans placed on a protein produced in plants and those placed on a protein produced by the dominant manufacturing method, mammalian cell culture. Lessening or completely eliminating these differences will greatly increase the acceptance level and viability of plant-based production techniques.

Enabling glycan production via the plant-based approach can result in lower capital costs and greater production efficiencies. In addition, a plant-based approach can produce a faster route to production, simpler downstream processing and provide nearly limitless capacity. Plant-based production accommodates a wide range of protein types, including some not possible with traditional production technologies.

Effective plant-based technology can also improve the efficacy of drug substances by overcoming the problem of incomplete glycosylation, the incomplete formation of human carbohydrate patterns. Incomplete glycosylation can result in increased costs of production due to more processing steps, reduced half-life of the protein in the body, increased immunogenicity and reduced clinical effectiveness. Eliminating this problem can result in improved drug properties, greater production efficiencies and, in some cases, additional patent protection for drug developers.