Improved nuclear waste disposal focus of $800K Department of Energy grant

An innovative method for removing radioactive elements from nuclear waste that could reduce the amount of total waste being generated through nuclear fission is the focus of a three-year, $800,000 grant from the Department of Energy through its Nuclear Energy University Program.

During nuclear fission, uranium atoms break down into smaller elements, which release high amounts of heat energy. Many of the resulting smaller elements are unstable and radioactive. They will eventually break into smaller particles and emit harmful radiation - alpha and beta particles and gamma radiation.

A recycling process for used nuclear fuel is under development by the DOE, but two radioactive elements - cesium and strontium, which are alkali/alkaline-earths - are the most challenging to isolate and remove, according to Hojong Kim , assistant professor of materials science and engineering , Penn State, and principal investigator on the project.

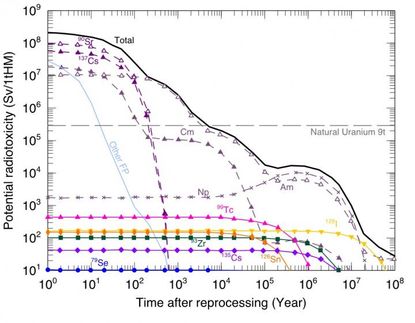

"Alkali and alkaline-earth elements are very strong and reactive metals, so it is hard to separate them from other elements," he said. "Cesium and strontium have a relatively short half-life - about 30 years - so they produce the highest amount of heat in the short term of all radioactive elements created through nuclear fission."

Currently, used nuclear fuels are fed into a liquid bath known as an electrolyte solution so that some elements, such as uranium, can be isolated, removed and reused. However, when barium, cesium and strontium interact with the solution, they react and change the solution's physical and chemical properties, making it unusable for nuclear fuel recycling.

"The easiest way to address this may include refreshing the electrolyte bath, but this will result in an excessive amount of useful electrolyte being wasted and increased operating costs. Furthermore, these electrolytes need to be mixed with glasses for safe, long-term nuclear waste disposal, creating a large volume of nuclear waste," said Kim.

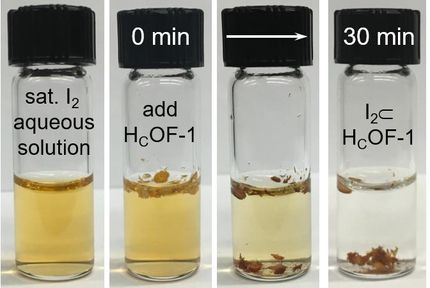

Rather than disposing of the bath entirely, Kim's team will investigate the use of electrochemical separation, a process that attracts specific elements based on their physical and chemical properties. They will use an electrolyte solution under development by the DOE that has not yet been implemented in commercial nuclear reactors. By adding a new liquid electrode --an electrically conductive material -- to the mix, the researchers hope to remove just the barium, cesium and strontium, while leaving the remainder of the solution intact.

"This would let us keep the electrolyte much longer, create less waste and separate out the nuclear waste for better management," he said.

The major challenge the team faces is that the electrolyte solution can contain over 20 different elements, each tugging at or repelling other elements with different forces. Kim's first goal is to investigate the fundamental thermodynamic properties -- solubility and chemical potential -- of a group of potential electrode elements -- antimony, bismuth and lead. After identifying a suitable electrode, Kim will work with scientists at Argonne National Laboratory to test the electrode.

Topics

Organizations

Other news from the department science

Get the chemical industry in your inbox

By submitting this form you agree that LUMITOS AG will send you the newsletter(s) selected above by email. Your data will not be passed on to third parties. Your data will be stored and processed in accordance with our data protection regulations. LUMITOS may contact you by email for the purpose of advertising or market and opinion surveys. You can revoke your consent at any time without giving reasons to LUMITOS AG, Ernst-Augustin-Str. 2, 12489 Berlin, Germany or by e-mail at revoke@lumitos.com with effect for the future. In addition, each email contains a link to unsubscribe from the corresponding newsletter.