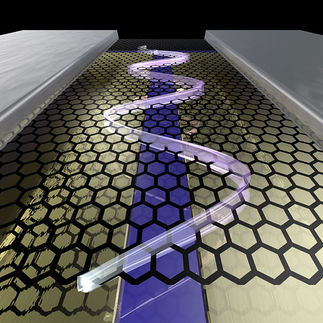

Graphene as an alternative transparent electrode for OLEDs

Until now transparent electrode materials for OLEDs have mainly consisted of indium tin oxide (ITO), which is expected to become economically challenging for the industry due to the shrinking abundance of indium. Therefore, scientists are intensively looking for alternatives. One promising candidate is graphene, whose application fields are more closely investigated in the project GLADIATOR („Graphene Layers: Production, Characterization and Integration“).

The project GLADIATOR, which is funded by the European Commission, has reached its midterm and has already achieved some successes. The aim of the project is the cost-effective production of high quality graphene at large area, which can then be used for numerous electrode applications. The usability of such applications will be demonstrated at the Fraunhofer FEP by integrating this graphene in OLEDs.

With graphene as an electrode, the researchers at the Fraunhofer FEP hope for flexible devices with higher stability. Beatrice Beyer, project coordinator, says: “Graphene is a very interesting material with many possibilities. Because of its opto-electrical properties and its excellent mechanical stability, we expect that the reliability of flexible electronics will be improved many times over.”

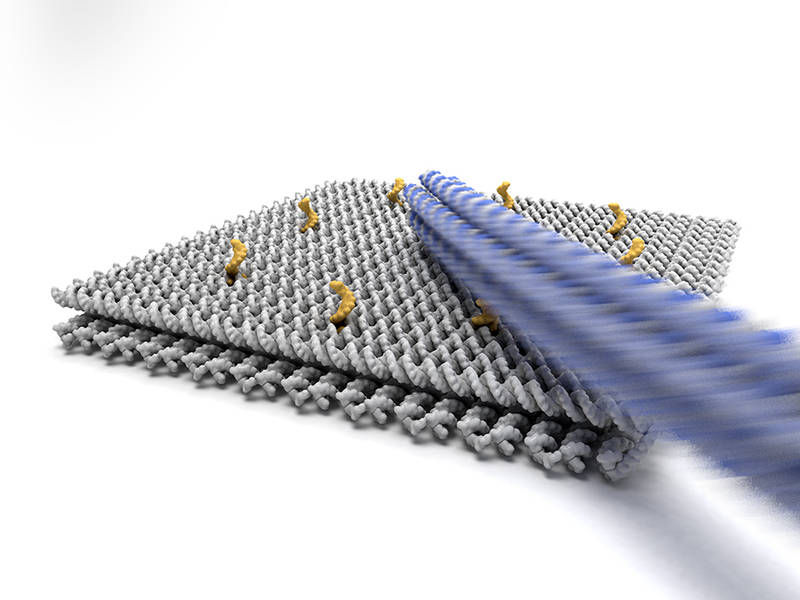

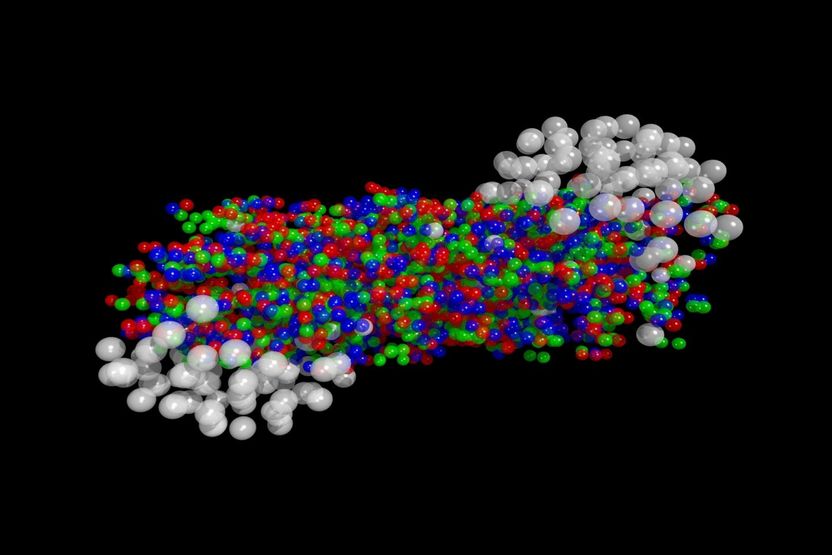

It is very important that no defects are added to the graphene which might reduce the quality of the electrode. In order to compete with the reference material ITO, the transparency and conductivity of graphene must be very high. Therefore, not only the process of electrode manufacturing is being optimized, but also different ways of doping graphene to improve its properties are being examined.

The Fraunhofer FEP is coordinating the GLADIATOR project and acts as an end-user of the graphene electrode. Scientists examine the integration of graphene and compare it to the reference material ITO. The sophisticated material properties of graphene must be maintained during the integration in organic devices. To this end, several methods for cleaning and structuring the graphene must be modified. In addition, the processes for different target substrates such as glass or flexible foil must be adapted and optimized. The first hurdles have been overcome thanks to a close cooperation between the consortium partners and the first defect-free OLEDs on transparent graphene electrodes have been realized on small areas. The target of the next one and a half years is to successfully illuminate large area OLEDs.

Other news from the department science

Get the chemical industry in your inbox

By submitting this form you agree that LUMITOS AG will send you the newsletter(s) selected above by email. Your data will not be passed on to third parties. Your data will be stored and processed in accordance with our data protection regulations. LUMITOS may contact you by email for the purpose of advertising or market and opinion surveys. You can revoke your consent at any time without giving reasons to LUMITOS AG, Ernst-Augustin-Str. 2, 12489 Berlin, Germany or by e-mail at revoke@lumitos.com with effect for the future. In addition, each email contains a link to unsubscribe from the corresponding newsletter.

Most read news

More news from our other portals

Last viewed contents

Artificial Cells - Porous molybdenum oxide capsules serve as models for biological ion-transport processes

Piecework at the nano assembly line - Fast computer control for molecular machines

I._M._Dharmadasa

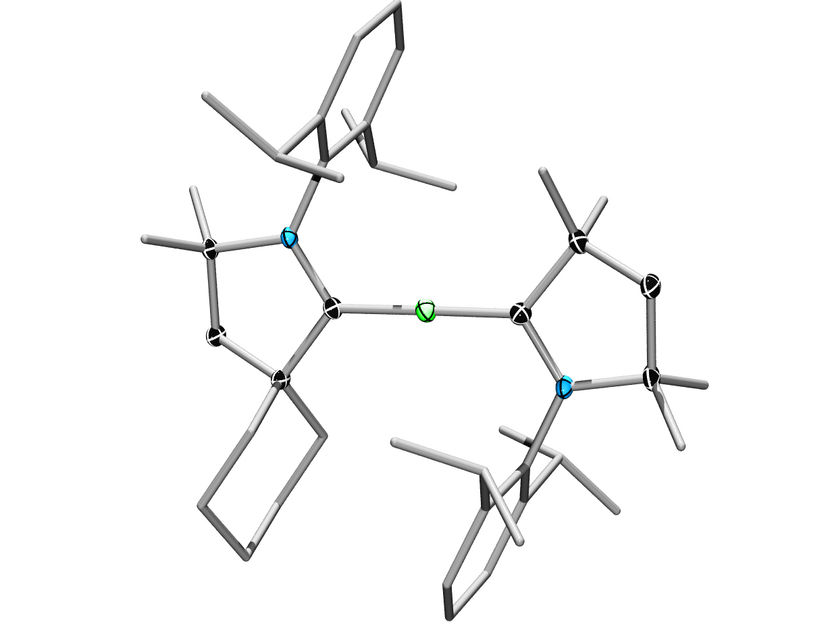

Soluble Elements from a New Corner of the Periodic Table

Table_of_nuclides,_25-48

Steam_drum

Møller-Plesset_perturbation_theory

Twisting graphene into spirals - Researchers synthesize helical nanographene

The most exotic fluid has an unexpectedly low viscosity

Gramicidin