Scientists watch metal melt in nanoseconds

Novel technique allows scientists to look deep into rocky planets in the lab

Advertisement

A pilot study opens a new path to analysing the interior of rocky planets in the lab. The research team, led by the University of Edinburgh and including scientists from DESY, has created high pressures and temperatures like those deep within the Earth and used the powerful LCLS X-ray laser at the US National Accelerator Laboratory SLAC to monitor the melting of the heavy metal bismuth under these extreme conditions in unprecedented detail. One surprising result: Bismuth melts much faster than expected at high pressure. The transition from solid to liquid took less than three nanoseconds, or three billionths of a second (0.000 000 003 seconds), as the scientists report in the journal Physical Review Letters. This is ten to a hundred times faster than previous estimates. The novel technique paves the way for the improved modelling of the interior of rocky planets of our own sun and of other stars (exoplanets).

“Thanks to the ultra short flashes of the X-ray laser, we could watch the samples melt in images taken only nanoseconds apart,” explained team leader Malcolm McMahon, a professor of physics at the University of Edinburgh. “Before, researchers could only estimate how long the melting process would take using indirect methods.” The analysis helps to understand the general behaviour of materials under extreme conditions.

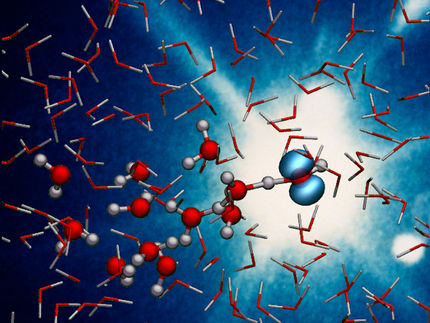

The scientists shot extremely powerful flashes of a green laser at thin bismuth slices, each with a thickness of only 0.02 millimetres. Each laser flash sent a strong shock wave racing through the material at 7000 kilometres per hour, producing up to 200,000 times atmospheric pressure and a temperature of several hundred degrees Celsius within the sample – similar to conditions found deep within rocky planets, for instance several hundred kilometres deep in the Earth's mantle.

The green laser flash was followed by an intense and ultra short X-ray laser pulse to determine the state of the sample. X-rays are diffracted in characteristic ways by solid samples, forming a distinctive pattern on the detector, or camera, which records the result. Liquid samples produce a completely different pattern. “Diffraction is an excellent way to measure melting, because it gives very clear results”, explained DESY scientist Hanns-Peter Liermann, a co-author of the study.

As each sample was destroyed by the intense X-ray laser, the scientists had to repeat their experiment with fresh samples 400 times, carefully delaying the X-ray pulse a little longer each time. This way they obtained a time series “movie” with nanosecond temporal resolution. “We saw the bismuth melt in less than three nanoseconds”, said Martin Gorman from the University of Edinburgh, the main author of the study. “Previous estimates ranged from tens to hundreds of nanoseconds.”

The team chose bismuth for their initial study because it behaves like other metals at extreme conditions, but at only modest pressures and temperatures. “Now that we can make these measurements in bismuth, we can make them in other materials, too,” said co-author Emma McBride who worked at Edinburgh during the experiment before joining DESY. New facilities like the X-ray laser European XFEL that is currently under construction in Hamburg will open up new possibilities to investigate materials at even more extreme conditions. “We now have a method to measure the melting of materials at extremely high pressures and temperatures”, said Gorman. “This really starts the ball rolling.”

Bismuth is a relatively rare element. But the new method allows the investigation of more common elements, too. “For instance, we would really like to know the behaviour of iron at pressures and temperatures well beyond those at the Earth's core,” said McMahon. “There are a lot of exotic planets out there beyond our solar system. If you can measure the melting of materials under their internal conditions, we can build accurate models for the interior of those exoplanets. This opens the door to a kind of remote ‘exoplanet geology’.”