Researchers pioneer use of capsules to save materials, streamline chemical reactions

Advertisement

Chemists working in a variety of industries and fields typically go through a laborious process to measure and mix reagents for each reaction they perform. And many of the common reagents they use sit for months or years on shelves in laboratories, where they can react with oxygen and water in the atmosphere, rendering them useless.

In a paper published in Nature, researchers at MIT describe a technique that could help avoid this costly waste, and greatly reduce the number of steps a chemist must perform to prepare common compounds for use in a wide range of chemical transformations.

Aaron C. Sather, the lead author of the paper, is a postdoc in the lab of Stephen Buchwald, the Camille Dreyfus Professor in Chemistry. He and his colleagues have harnessed the power of a small, simple technology that could transform the benchtop practice of organic chemistry: the capsule.

Some labs use what is known as a "glove box," an inert container that permits researchers to manipulate reagents in a controlled environment, isolated from the oxygen, carbon dioxide, and water in ambient air. But many laboratories in industry and academia don't have glove boxes because they're expensive to maintain, and take up precious space, Sather says. As a result, many chemists avoid performing certain useful, but complicated, reactions because they require a glove box.

"If you can grab the reagents off the shelf and get the reaction to work without that expertise or a glove box, it's much more accessible," Sather says.

Paraffin delivery vehicles

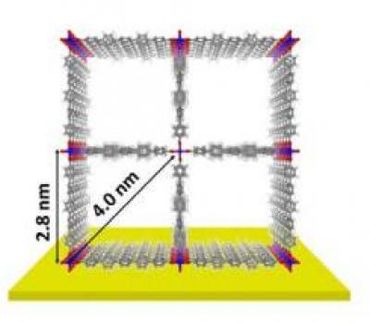

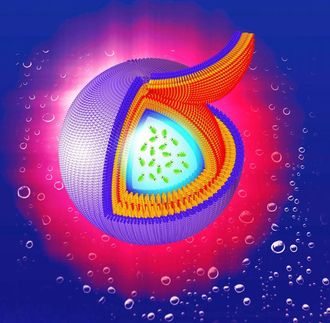

Building on previous work by Douglass Taber at the University of Delaware, the researchers tried to disperse mixtures of reagents in molten paraffin wax, which has been demonstrated to protect oxygen- and water-sensitive compounds for long periods of time. But as the material cooled, certain dense reagents, such as cesium fluoride, would settle to the bottom. The scientists then decided to try making small capsules out of paraffin, enabling precise estimates of the contents for grab-and-go use.

"We thought, if we could enclose multiple reagents [and] catalysts in some way and actually know how much we put in," Sather says, "we could dramatically simplify chemical synthesis with these single-use capsules."

Paraffin's physical properties make it ideal as a delivery vehicle for all kinds of chemical compounds. "We wanted something that was inert, a long-chain hydrocarbon," Sather says, "that would have no competing side reactions with both catalyst and reagents. It's largely unreactive. Paraffin is insanely cheap, and nice and easy to work with. Paraffin doesn't pick up any water - it's just like grease."

Upon heating, the paraffin capsule melts/dissolves in the reaction solvent, releasing its contents. After the reaction is finished, the paraffin can then be removed through precipitation, filtration, and chromatography.