Queen's researchers develop technology to reduce cost of purifying natural gas

Advertisement

Researchers at Queen's University Belfast have developed a cutting-edge method of reducing the carbon dioxide content of natural gas, a process of major economic and environmental importance in the oil and gas industry.

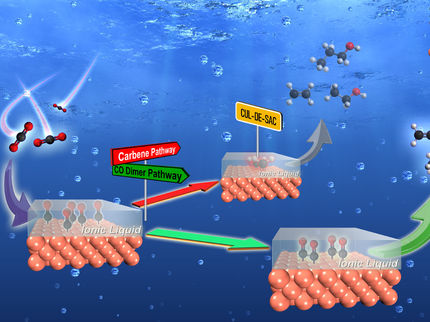

A team of researchers in the Queen's University Ionic Liquid Laboratories (QUILL) Research Centre has developed a technology that uses a mixture of water and ionic liquids (salts which are liquid under ambient conditions) to remove carbon dioxide from raw natural gas extracted from natural reservoirs under the sea.

The new process is aimed at reducing the global environmental and economic costs of purifying natural gas, which is by far the cleanest burning fuel available in large amounts. In comparison to current conventional 'amine' purifying systems, which use volatile and corrosive materials, the new ionic liquid system is safer, more efficient, and more environmentally friendly.

The process offers a range of commercial and industrial opportunities. It is compact enough to be utilised on off-shore platforms or installed on land-based gas-processing plants, and once captured the carbon dioxide may be stored, reprocessed, or used for enhanced oil recovery.

Dr David Wassell, who led the team from the Queen's University Ionic Liquid Laboratories (QUILL) Research Centre, said: "Using ionic liquids to remove the carbon dioxide from natural gas could have significant impact on the gas processing industry, particularly with the promise of using the carbon dioxide for enhanced oil recovery. It could make a significant contribution to reducing the environmental impact caused by this energy source."

Project coordinator, Dr Natalia Plechkova, from the Queen's University Ionic Liquid Laboratories (QUILL) Research Centre, said: "This joint project, developed with the global energy company PETRONAS, shows the progress which can be made in genuinely collaborative industry-university projects. The key to success was an integrated team approach."

"This is the latest example of the commitment of researchers and staff at Queen's to advancing knowledge and achieving excellence for the benefit of society."

Most read news

Other news from the department science

Get the chemical industry in your inbox

By submitting this form you agree that LUMITOS AG will send you the newsletter(s) selected above by email. Your data will not be passed on to third parties. Your data will be stored and processed in accordance with our data protection regulations. LUMITOS may contact you by email for the purpose of advertising or market and opinion surveys. You can revoke your consent at any time without giving reasons to LUMITOS AG, Ernst-Augustin-Str. 2, 12489 Berlin, Germany or by e-mail at revoke@lumitos.com with effect for the future. In addition, each email contains a link to unsubscribe from the corresponding newsletter.