Bayer MaterialScience: Further milestone in the manufacture of plastics from CO2

Company intends to replace petroleum with carbon dioxide

Bayer MaterialScience has taken another major step toward using CO2 for plastic production from 2016. A production line is currently under construction for this purpose at the Dormagen site in Germany. A chemical reactor weighing some 25 metric tons has now been put in place at the heart of this line. “We are right on schedule,” explained Dr. Karsten Malsch, overall project manager.

Little by little the customized reactor glides into the very heart of the new CO2-production-line at Bayer MaterialSciences’ site in Dormagen, Germany.

Bayer MaterialScience AG

The last major part – a CO2 tank – is due to be installed in the fall. This will take the construction of the 15 million euro plant into the homestretch. “If everything continues to run smoothly we will be able to start operations at the beginning of the coming year,” says Malsch. That will mean construction will have taken a good year to complete.

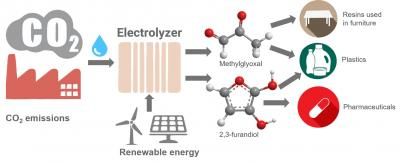

Bayer MaterialScience intends to use the new production line as part of the “Dream Production” project and for the first time integrate carbon dioxide as a raw material for polyols on a commercial scale. Polyols are crucial precursors for manufacturing foam. The line is designed for an annual production capacity of 5,000 metric tons. The idea is for the innovative polyol, which contains approximately 20 percent CO2, to initially be used in the manufacture of polyurethane foam mattresses.

CO2 replacing petroleum

Intensive tests have shown that the material using CO2 is at least as good as conventional products. The carbon dioxide replaces some of the petroleum that these kinds of polyols and polyurethanes are usually based on. “The plastics industry has long been looking for an alternative raw material basis to relieve the reliance on increasingly scarce fossil fuels,” explained Malsch. There is also growing demand for sustainable products in society. “We believe that our new process can offer a solution in both these areas.”

Some scientific groundwork was required in order to use CO2 in plastics production. Bayer MaterialScience performed this in collaboration with the CAT Catalytic Center, a research institute at Aachen University. The greatest challenge lay in finding a catalyst that would cause the carbon dioxide, which is chemically very inert, to react efficiently with other substances. The partners discovered the appropriate catalyst.

The research and development work is still ongoing: Bayer MaterialScience hopes to further increase the proportion of CO2 in the products in the future. At the same time, it also aims to increase the number of CO2-based plastics.

Organizations

Other news from the department manufacturing

Get the chemical industry in your inbox

By submitting this form you agree that LUMITOS AG will send you the newsletter(s) selected above by email. Your data will not be passed on to third parties. Your data will be stored and processed in accordance with our data protection regulations. LUMITOS may contact you by email for the purpose of advertising or market and opinion surveys. You can revoke your consent at any time without giving reasons to LUMITOS AG, Ernst-Augustin-Str. 2, 12489 Berlin, Germany or by e-mail at revoke@lumitos.com with effect for the future. In addition, each email contains a link to unsubscribe from the corresponding newsletter.