Blending is the Trick: Tailored Pores in Block Copolymer Membranes

A simple trick generates custom-tailored pores. Maryam Radjabian has developed a surprisingly uncomplicated method for obtaining the desired pore size in block copolymer membranes. The results of her research were published in Advanced Materials.

Tailored Pore Sizes in Integral Asymmetric Membranes Formed by Blends of Block Copolymers

HZG, Abetz

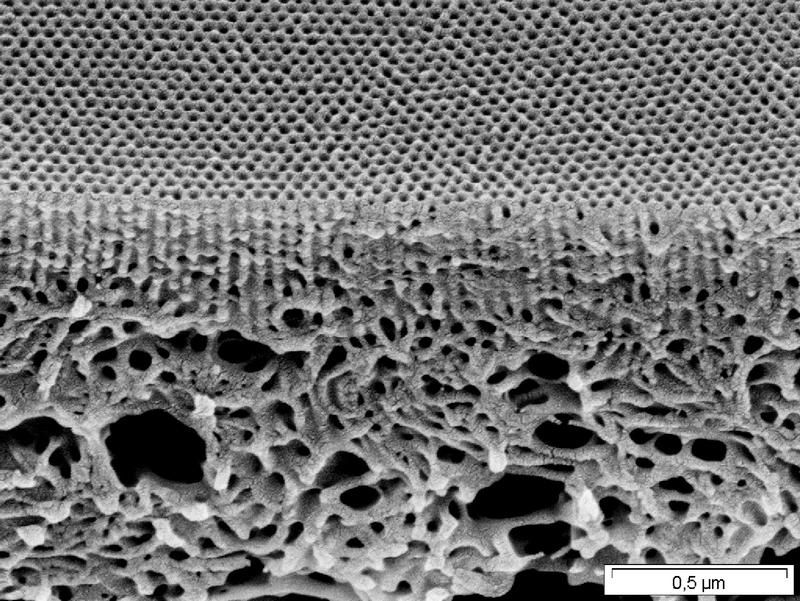

Whether it’s water treatment or virus and protein separation, porous membranes are utilised in many different separation functions. What is particularly fascinating and highly promising is isoporous membrane production from block copolymers. Under suitable conditions, block copolymers can form highly ordered structures, ideally uniform pores, through self-assembly.

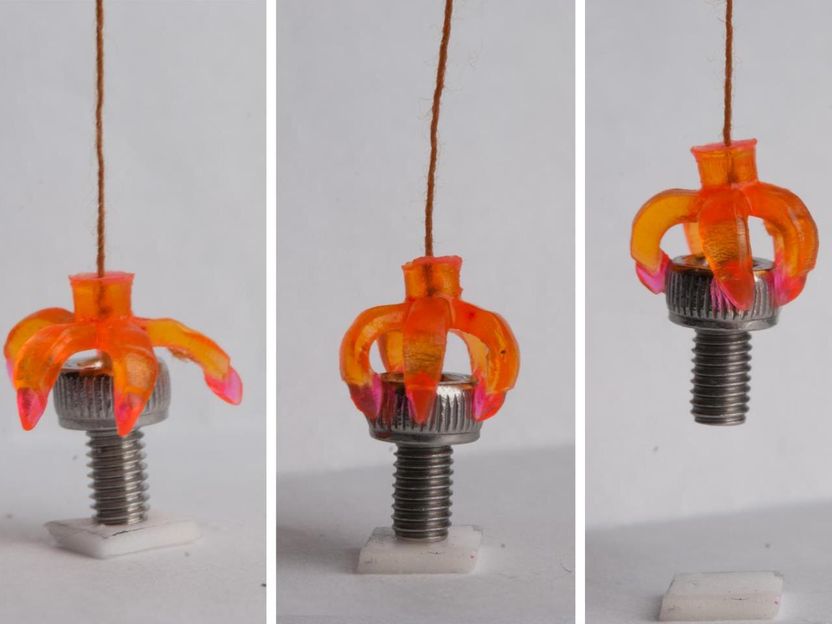

In order to develop effective membranes for special separation functions, the correct pore size is crucial. This objective presents the greatest challenge: how must the block copolymer be composed in order to obtain the desired pore size? To date, for every newly developed isoporous membrane a special block copolymer was synthesized, which then resulted in the necessary pore size. In cooperation with the director of Geesthacht’s Institute of Polymer Research, Prof. Volker Abetz, Dr. Maryam Radjabian has now developed a time-saving and surprisingly simple method: by blending of two block copolymers, the pore size can be adjusted via the blending ratio.

The two block copolymers consist of the same monomers but differ in the number of repetition units in the blocks. A different pore size then arises in the particular membrane cast from each block copolymer. Dr. Radjabian’s concept of obtaining an average pore size by blending two block copolymers has been corroborated in experiments.

This opens up entirely new possibilities for designing new membranes. The scientist at the Institute of Polymer Research explains, “There is a substantial advantage in not having to synthesize a precisely suitable block copolymer to obtain the desired pore size, but in simply mixing two approximately suitable copolymers together.”

Original publication

Other news from the department science

These products might interest you

Anopore™ by Cytiva

Precise filtration made easy with Anopore inorganic membranes

The aluminum oxide filter membrane that can increase the purity or yield of your analyte

Hahnemühle LifeScience Catalogue Industry & Laboratory by Hahnemühle

Wide variety of Filter Papers for all Laboratory and Industrial Applications

Filtration Solutions in the Life Sciences, Chemical and Pharmaceutical Sectors

Get the chemical industry in your inbox

By submitting this form you agree that LUMITOS AG will send you the newsletter(s) selected above by email. Your data will not be passed on to third parties. Your data will be stored and processed in accordance with our data protection regulations. LUMITOS may contact you by email for the purpose of advertising or market and opinion surveys. You can revoke your consent at any time without giving reasons to LUMITOS AG, Ernst-Augustin-Str. 2, 12489 Berlin, Germany or by e-mail at revoke@lumitos.com with effect for the future. In addition, each email contains a link to unsubscribe from the corresponding newsletter.