VTT creates efficient method of producing metallic nanoparticles

Advertisement

VTT Technical Research Centre of Finland Ltd has developed a new, cost-efficient method of producing various types of metallic nanoparticles. Nanoparticles can be used in applications such as conductive and magnetic inks, medical diagnostics and drug dosing, tailoring the electrical and magnetic properties of polymers and energy technology. VTT is seeking a party interested in commercialising the technique.

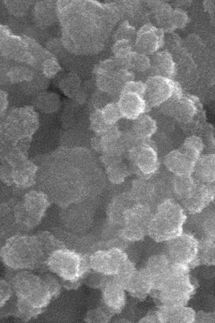

VTT's aerosol technology reactor for nanoparticle production can generate a variety of pure metal particles, particles of various alloys and carbon-coated particles. The reactor can efficiently produce hundreds of grammes or even kilogrammes of nanoparticles per day.

"Demand has outstripped supply in the nanoparticle markets. This has been an obstacle to the development of product applications; nano-metal composites are scarce and often available in small quantities only. We wanted to demonstrate that it was possible to produce nanomaterials in considerable quantities cost-effectively,” comments Ari Auvinen of VTT, head of the research team.

When developing the reactor, the aim was to achieve a production figure of 200–3,000 grammes per day. This has already been clearly exceeded. Due to the extremely small material wastage incurred when using this equipment, remote-control production can be maintained for several days. In most cases, industrial production of metallic nanoparticles involves chemical reduction in liquid solutions, which requires the design of product-specific solutions. Plasma synthesis, which consumes large amounts of energy and involves significant material wastage, is another generally used method.

In the design of the reactor developed by VTT, the scalability and cost-effectiveness of the synthesis process were key criteria. For this reason, synthesis is performed under air pressure at a comparatively low temperature. This means that the equipment can be built from materials commonly used in industry and energy consumption is low. The process generates an extremely high particle concentration, enabling a high production speed but with low gas consumption. In addition, even impure metallic salts can be used as a raw material, which keeps the price low.

VTT has demonstrated the practical functionality of its reactor by testing the production of various nanometals, metallic compounds and carbon-coated materials. Materials such as carbon-coated magnets, which can be used as catalysts in biorefineries – say, in the production of biofuels – have been produced in the reactor. Following synthesis, magnets used as catalysts can be efficiently gathered in and recycled back into the process.

Nanoparticles have also been tested in the manufacture of magnetic inks and inks that conduct electricity in printed electronics. For example, VTT succeeded in using a permalloy ink to print a magnetically anisotropic material, which can be used in the manufacture of magnetic field sensors.

VTT's third application trial involved the prevention of microwave reflection. The tests showed that reflection can be reduced by even 10,000 times in polymers, by adding particles which increase radar wave attenuation.

VTT's researchers believe that the reactor has many applications in addition to those already mentioned. The silicon nanoparticles it produces may even enable lithium battery capacity to be boosted by a factor of 10. Other possible applications, all of which require further investigation, include high permeability polymers, nanomagnets for medical diagnostics applications, materials for the 3D printing of metal articles, and silicon-based materials for thermoelectric and solar power components.

VTT is currently seeking a party interested in commercialising the technique.