ThyssenKrupp Industrial Solutions awarded planning contract for propane dehydrogenation plant

ThyssenKrupp Industrial Solutions is making its Steam Active Reforming (STAR) process available to Formosa Plastics Corporation (FPC) for a propane dehydrogenation (PDH) plant in Texas, USA. The PDH plant is to be built at the petrochemical complex in Point Comfort. The contract awarded to ThyssenKrupp Industrial Solutions includes licensing, basic engineering, detail engineering for the key equipment, delivery of the catalyst (STAR catalyst®) and technical support during the entire project execution.

Hans-Theo Kühr, CEO of the Process Technologies business unit at ThyssenKrupp Industrial Solutions: “Having already acquired several major fertilizer plant contracts for as a result of the shale gas boom in the USA, we are confident we can now profit from forthcoming investments in propane dehydrogenation plants. This contract is an important step. With our engineering expertise and technological capabilities, we help our customers make their production processes more efficient so as to gain an edge in their markets.”

Developed by Uhde, the promising STAR process® for dehydrogenation of light hydrocarbons has a broad range of applications. The propylene produced is one of the most important base materials in the petrochemical industry. Among other things it is used to make polypropylene, a popular polymer used e.g. in the production of food packaging, toys, and textiles such as carpets.

“The advantages of the STAR process® lie in its high flexibility and robustness in operation and its efficiency in manufacturing the desired products. This significantly reduces investment, operating and maintenance costs for our customers,” says Dr. Benno Lüke, head of the Chemicals/Oil & Gas operating unit at ThyssenKrupp Industrial Solutions.

The PDH plant in Point Comfort will have a capacity of 545,000 tons per year of propylene and is part of the Point Comfort petrochemical complex expansion announced by FPC in February 2012.

Most read news

Organizations

Other news from the department business & finance

Get the chemical industry in your inbox

By submitting this form you agree that LUMITOS AG will send you the newsletter(s) selected above by email. Your data will not be passed on to third parties. Your data will be stored and processed in accordance with our data protection regulations. LUMITOS may contact you by email for the purpose of advertising or market and opinion surveys. You can revoke your consent at any time without giving reasons to LUMITOS AG, Ernst-Augustin-Str. 2, 12489 Berlin, Germany or by e-mail at revoke@lumitos.com with effect for the future. In addition, each email contains a link to unsubscribe from the corresponding newsletter.

Most read news

More news from our other portals

Last viewed contents

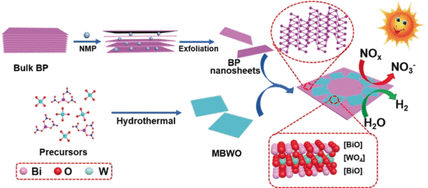

Semiconductors Combine Forces in Photocatalysis - Active photocatalyst: 2D/2D heterojunction of black phosphorus and bismuth tungstate

Discovery of a 'dark state' could mean a brighter future for solar energy - Maximum theoretical efficiency of solar cells could increase from 31 to 44 percent