Improved quality control of silicon carbide epiwafers by a new fast and contactless inline inspection tool

A new fast and contactless Defect Luminescence Scanner (DLS) for photoluminescence imaging of 4H-SiC epiwafers was developed under coordination of Fraunhofer IISB together with Intego GmbH. This DLS system enables a more efficient optimization of the production process of SiC epiwafers as well as an inline quality control along the device production chain. This will contribute to cost reduction in material and device production, and helps accelerating the further commercialization of SiC power devices.

With respect to structural defects, such as micropipes or other dislocation types, and their densities in substrates and epilayers, the material quality of silicon carbide (4H-SiC) has been improved greatly within the last years. But still, the performance of especially SiC bipolar devices and the yield of device production may be limited by residual structural defects in the epiwafers. Such defects originate in the substrate material or are generated during the epitaxial process like, e.g. down-fall particles, stacking faults, and dislocations.

To date, several characterization methods are well established for identification and distribution of such defects on the wafer level, but they are destructive (defect selective etching), cost-intensive (synchrotron x-ray topography), or time-consuming (both defect selective etching and x-ray topography). Hence, they are not suitable for a fast inline quality control of the material preparation and device production. As a non-destructive, contactless method allowing for identification of structural defects of 4H-SiC at room temperature, the photoluminescence (PL) technique is well known. In PL images, structural defects appear either as bright or dark items on the “grey” SiC background as 4H-SiC itself shows a low PL intensity due to its indirect band gap.

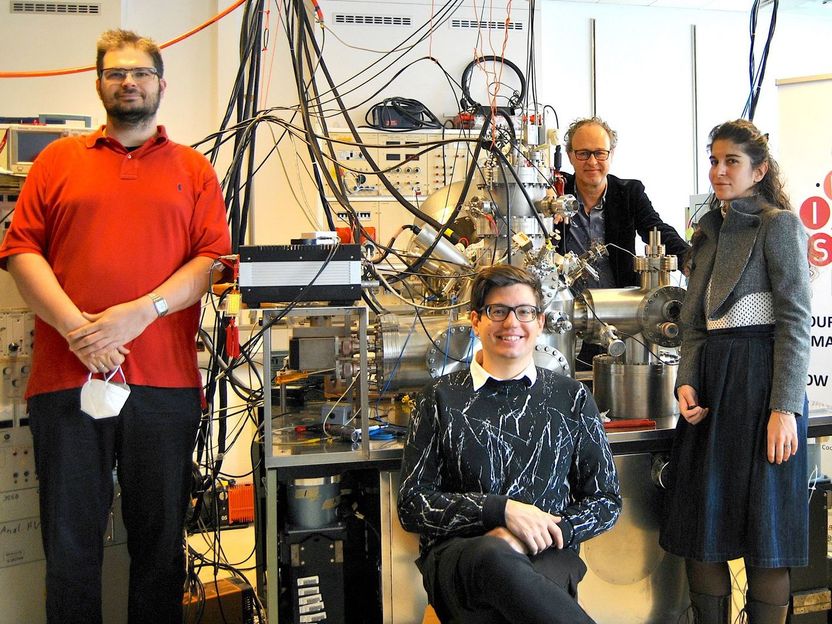

However, so far no PL setup exists which is fast enough for an inline defect analysis on full waferscale within a production environment. This obstacle has now been overcome in the course of the “SiC-WinS” project, funded by the Bavarian Research Foundation (BFS) under contract number AZ-1028-12. Together with the metrology specialist Intego Vision Systeme GmbH, the new PL imaging tool called defect luminescence scanner (DLS) was designed and fabricated under coordination of Fraunhofer IISB. The DLS allows for short PL measurement cycles and high throughput of SiC epiwafers at a high lateral resolution of 5 μm.

The DLS system is installed at Fraunhofer IISB and consists of a UV laser operating at 325 nm wavelength for PL excitation, a sample stage for scanning the SiC epiwafer, and an electron multiplying charge-coupled device (EMCCD) camera for fast image recording at a high signal-to-noise ratio. The high lateral resolution of 5 μm is achieved by a magnifying objective lens in front of the camera. For identification of defect types by their spectral fingerprints, different band-pass filters are installed. The DLS system can determine the defect types and their distribution on SiC epiwafers up to 150 mm diameter in less than 30 minutes. A routine for automated defect identification and counting in order to predict directly the device yield per epiwafer is currently under development.

Organizations

Other news from the department research and development

Get the chemical industry in your inbox

By submitting this form you agree that LUMITOS AG will send you the newsletter(s) selected above by email. Your data will not be passed on to third parties. Your data will be stored and processed in accordance with our data protection regulations. LUMITOS may contact you by email for the purpose of advertising or market and opinion surveys. You can revoke your consent at any time without giving reasons to LUMITOS AG, Ernst-Augustin-Str. 2, 12489 Berlin, Germany or by e-mail at revoke@lumitos.com with effect for the future. In addition, each email contains a link to unsubscribe from the corresponding newsletter.

Most read news

More news from our other portals

Last viewed contents

Hyundai_Enercell

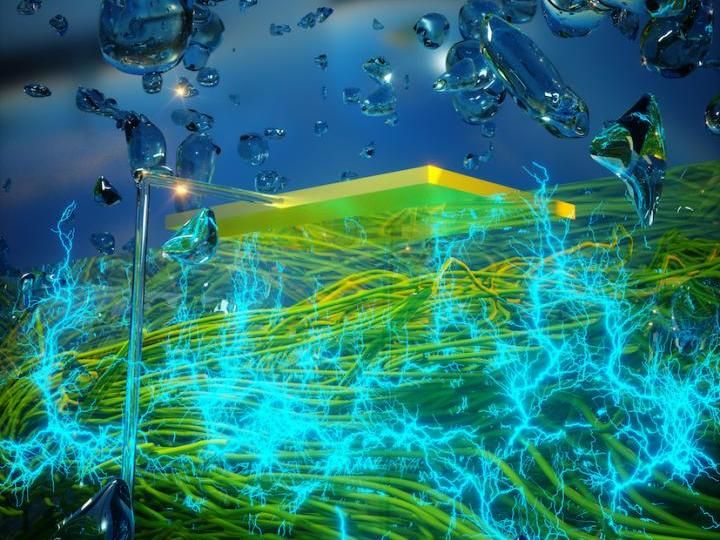

A micro-supercapacitor with unmatched energy storage performance

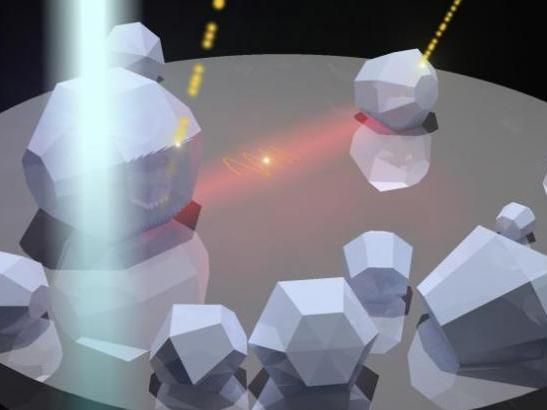

On the edge of friction - Precise insight into how two microscopic surfaces slide over one another could help in the manufacture of low-friction surfaces

New technique 'sees' radioactive material even after it's gone

Orlov_(diamond)

Old Mystery Solved: a "New Kind of Electrons" - Why do certain materials emit electrons with a very specific energy?

Killer silk: Making silk fibers that kill anthrax and other microbes in minutes

Putting quantum scientists in the driver's seat

Altana Pharma invests in new High Throughput Screening system from Thermo Electron