Nanocellulose sponges to combat oil pollution

Advertisement

A new, absorbable material from Empa wood research could be of assistance in future oil spill accidents: a chemically modified nanocellulose sponge. The light material absorbs the oil spill, remains floating on the surface and can then be recovered. The absorbent can be produced in an environmentally-friendly manner from recycled paper, wood or agricultural by-products.

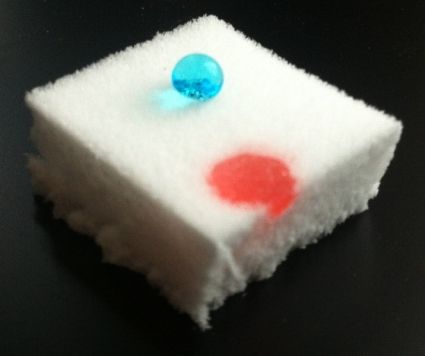

Demonstration of the oleophilic and at the same time hydrophobic properties of a silylated nanocellulose sponge: A droplet of water (blue) sits on the surface, whereas a droplet of oil (red) is absorbed by the material.

Empa

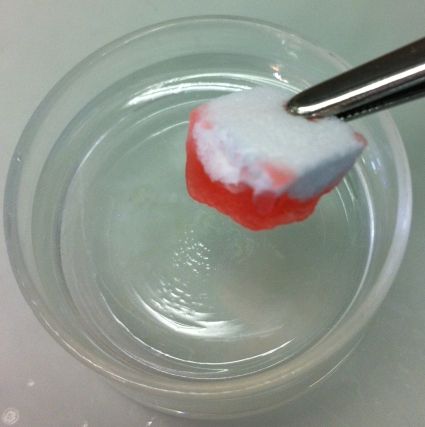

The sponge remains afloat and can be pulled out easily. The oil phase is selectively removed from the surface of water.

Empa

All industrial nations need large volumes of oil which is normally delivered by ocean-going tankers or via inland waterways to its destination. The most environmentally-friendly way of cleaning up nature after an oil spill accident is to absorb and recover the floating film of oil. The Empa researchers Tanja Zimmermann and Philippe Tingaut, in collaboration with Gilles Sèbe from the University of Bordeaux, have now succeeded in developing a highly absorbent material which separates the oil film from the water and can then be easily recovered, “silylated” nanocellulose sponge. In laboratory tests the sponges absorbed up to 50 times their own weight of mineral oil or engine oil. They kept their shape to such an extent that they could be removed with pincers from the water. The next step is to fine tune the sponges so that they can be used not only on a laboratory scale but also in real disasters. To this end, a partner from industry is currently seeked.

One step production – from cellulose plants

Nanofibrillated Cellulose (NFC), the basic material for the sponges, is extracted from cellulose-containing materials like wood pulp, agricultural by products (such as straw) or waste materials (such as recycled paper) by adding water to them and pressing the aqueous pulp through several narrow nozzles at high pressure. This produces a suspension with gel-like properties containing long and interconnected cellulose nanofibres .

When the water from the gel is replaced with air by freeze-drying, a nanocellulose sponge is formed which absorbs both water and oil. This pristine material sinks in water and is thus not useful for the envisaged purpose. The Empa researchers have succeeded in modifying the chemical properties of the nanocellulose in just one process step by admixing a reactive alkoxysilane molecule in the gel before freeze-drying. The nanocellulose sponge loses its hydrophilic properties, is no longer suffused with water and only binds with oily substances.

In the laboratory the “silylated” nanocellulose sponge absorbed test substances like engine oil, silicone oil, ethanol, acetone or chloroform within seconds. Nanofibrillated cellulose sponge, therefore, reconciles several desirable properties: it is absorbent, floats reliably on water even when fully saturated and is biodegradable.

Original publication

ltralightweight and Flexible Silylated Nanozellulose Sponges for the Selective Removal of Oil from Water, Zhang Z., SeÌbe G., Rentsch D., Zimmermann T., Tingaut P., Chem. Mater. 2014, 26, 2659−2668.