Sunlight to jet fuel

A European consortium with the participation of ETH Zurich has experimentally demonstrated the first ever production of jet fuel via a thermochemical process using concentrated solar energy. Researchers from ETH Zurich conducted the EU funded project Solarjet together with the German Aerospace Center (DLR), the fuel company Shell, the think-tank Bauhaus Luftfahrt, and the consulting firm Arttic.

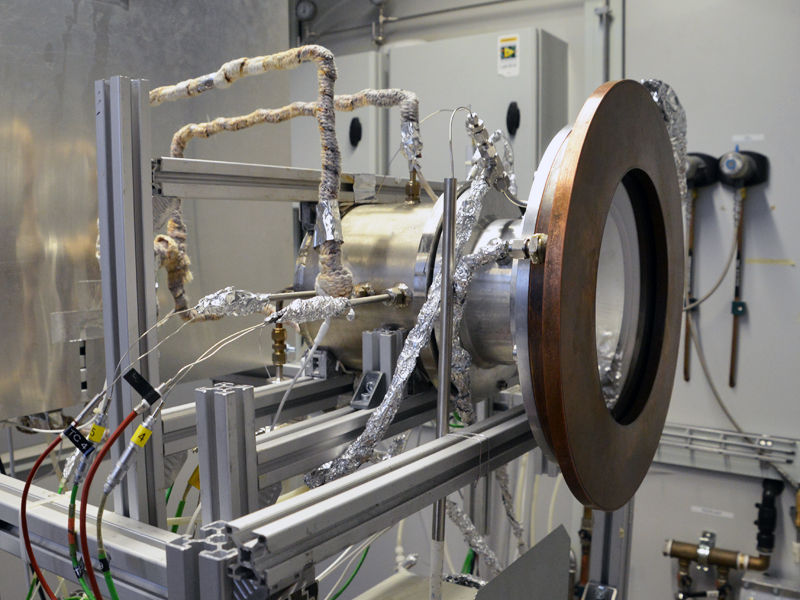

The solar reactor (left) is irradiated with concentrated light from the high-flux solar simulator.

Peter Rüegg / ETH Zürich

Close-up of the solar reactor.

Peter Rüegg / ETH Zürich

The key component of the production process of sustainable “solar kerosene” is a high-temperature solar reactor developed by the group of Aldo Steinfeld, Professor of Renewable Energy Carriers at ETH Zurich and Head of the Solar Technology Laboratory at the Paul Scherrer Institute. The reactor contains a porous ceramic solar absorber made of the metal oxide ceria, which enables the molecular splitting of water and CO2 in a cyclic two-step reduction-oxidation (redox) process.

Syngas for kerosene synthesis

The first, energy-intensive step proceeds at 1500 degrees Celsius using concentrated solar radiation as the energy source. The metal oxide releases oxygen, assuming a reduced state. In the second step at 700 degrees Celsius, the reduced metal oxide reacts with water and CO2, thus re-acquiring oxygen. As the metal oxide is thereby returned to its original state, it can enter the next cycle of the redox process. The net chemical product is synthesis gas – or syngas – a gas mixture of hydrogen (H2) and carbon monoxide (CO), which serves as the precursor for the synthesis of liquid hydrocarbon fuels.

“We were able to successfully perform 240 consecutive cycles,” says Daniel Marxer, PhD student of Steinfeld’s group. The yield was 750 litres of syngas, which were shipped in a pressurized vessel from Zurich to Amsterdam. There, at a Shell research centre, the solar syngas was finally converted into kerosene by an established method (Fischer-Tropsch process).

Exploring the industrial application

In a next phase the scientists aim to optimise the solar reactor technology. “Enhanced heat transfer and fast reaction kinetics are crucial for maximizing the solar-to-fuel energy conversion efficiency,” says Steinfeld. The industrial application in megawatt solar tower systems, such as those already applied commercially for electricity generation, is being explored.

It might also be possible in the future to obtain the required feedstock of CO2 from flue gas separation or directly from atmospheric air, thereby closing the material cycle for a CO2-neutral process. The scientists are well aware of the large areas required for fuelling commercial aviation with solar kerosene. “The long term goal is to reach a 15 per cent efficiency with the solar-driven cyclic process“, says Steinfeld. 20,000 litres kerosene per day could then be produced in a solar tower system of one square kilometre.

Most read news

Other news from the department science

Get the chemical industry in your inbox

By submitting this form you agree that LUMITOS AG will send you the newsletter(s) selected above by email. Your data will not be passed on to third parties. Your data will be stored and processed in accordance with our data protection regulations. LUMITOS may contact you by email for the purpose of advertising or market and opinion surveys. You can revoke your consent at any time without giving reasons to LUMITOS AG, Ernst-Augustin-Str. 2, 12489 Berlin, Germany or by e-mail at revoke@lumitos.com with effect for the future. In addition, each email contains a link to unsubscribe from the corresponding newsletter.