Reduced ignition propensity requirement may cause changes to cigarette smoke chemistry

Scientists have created temperature maps to explain how reduced ignition propensity (RIP) bands influence cigarette burn rate and possibly the chemical composition of the resulting smoke.

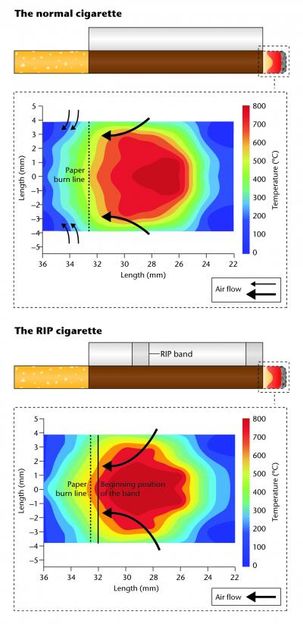

This image shows the contrasting burning temperature distribution between a normal cigarette and a reduced ignition propensity cigarette burning at the paper band.

British American Tobacco

RIP bands are designed to make a cigarette go out if it is not being actively smoked. Previous studies have shown a significant increase in levels of biomarkers for a few polycyclic aromatic hydrocarbons (PAHs) in smokers of RIP cigarettes, although the toxicological implications of these increases are currently unknown.

RIP bands are like speed bumps' placed on the paper along the length of cigarette. They are made of 5-6mm wide bands of low-permeability biopolymer coating designed to make the cigarette go out if it is not being smoked. It is difficult for oxygen to diffuse through these bands, which impacts the temperature inside the cigarette and reduces its tendency to smoulder.

There has been little detailed study of how RIP bands affect temperature distributions inside a burning cigarette. Now, for the first time, research by the Zhengzhou Tobacco Research Institute of Chinese National Tobacco Company and British American Tobacco reveals that RIP bands cause at least two significant temperature changes.

Using fine thermocouples, the researchers systematically measured temperature profiles within the burning tips of an RIP cigarette and a regular cigarette without bands but otherwise identical. Measurements were taken while they smouldered and then during a 2-second puff using a smoking machine – through an RIP band in the case of the RIP cigarette. Using these measurements, researchers digitally constructed a series of temperature maps, and calculated the corresponding volumes of different temperatures (burn volumes) inside the burning tips.

These were compared over time for the two types of cigarettes. Before the puff (while smouldering), the two types of cigarette burned in almost the same way until the paper burn line approached the RIP band. However, the central region of the RIP cigarette had a lower temperature and reduced burn volume some 20 seconds before the edge of paper burn line reached the RIP band, indicating that the RIP band, restricting oxygen availability from the unburnt paper direction, was able to suppress smouldering well ahead of the approaching burning tip.

Halfway through the 2-second puff, which is when airflow is at its highest, the temperature map was markedly different for the RIP cigarette: there was a lower average burn rate through the band due to a lag in reaching peak temperature, which continued at the end of the puff.

The researchers suggest that this difference may be due to a change in the path of air influx brought about because the RIP band carries more and denser material than a normal cigarette paper and, even after burning, the band still maintains a higher resistance to air flow than non-banded cigarette paper. Further research will be required to determine whether the change in temperature distribution of RIP cigarettes, as revealed by this work, influences smoke composition in a way that explains the above mentioned biomarker increases in PAHs.

Nevertheless, the random distribution of RIP bands means that most puffs on an RIP cigarette will occur in non-banded areas. However, smoking into RIP bands might have a bigger influence on the overall cigarette smoke composition if smokers take a bigger puff through the bands in order to prevent the cigarette from going out, says Lead researcher Dr Chuan Liu of British American Tobacco.

Most read news

Other news from the department science

Get the chemical industry in your inbox

By submitting this form you agree that LUMITOS AG will send you the newsletter(s) selected above by email. Your data will not be passed on to third parties. Your data will be stored and processed in accordance with our data protection regulations. LUMITOS may contact you by email for the purpose of advertising or market and opinion surveys. You can revoke your consent at any time without giving reasons to LUMITOS AG, Ernst-Augustin-Str. 2, 12489 Berlin, Germany or by e-mail at revoke@lumitos.com with effect for the future. In addition, each email contains a link to unsubscribe from the corresponding newsletter.

Most read news

More news from our other portals

Last viewed contents

Artkim Group - Istanbul, Turkey

200 mio. € investment in green hydrogen pioneer Hy2gen AG - Capital will be deployed on e-fuels to decarbonise industry and transportation sectors

![Potential for a green energy economy based on hydrogen - First Characterization of a Sensory [FeFe] Hydrogenase](https://img.chemie.de/Portal/News/110728_f0g-fwqjA.jpg?tr=n-xzoom)