TU/e signs agreement with paper industry for research into revolutionary solvent

New process can reduce energy consumption of paper industry by 40 percent

Eindhoven University of Technology (TU/e) signed an agreement last week with 14 European paper producers for the further development of a breakthrough new solvent. This new solvent, developed by TU/e professor Maaike Kroon, will potentially enable the paper industry to make big energy savings in production and to use raw materials more efficiently. The European paper industry has high expectations of the new solvent. “This is a game changer, and it means the paper industry will look very different 20 years from now”, said Henk van Houtum, chairman of VNP, the Royal Netherlands’ paper and board association.

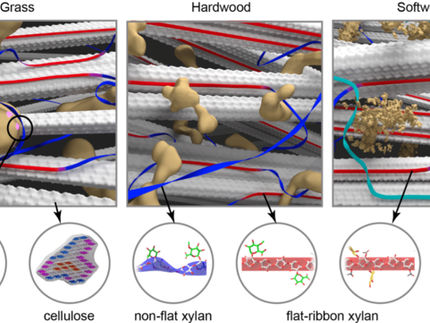

Kroon discovered that wood fibers easily dissolve in specific ‘deep eutectic solvents’ (DES). In the production of paper, the basic vegetable material (lignocellulose), such as wood chips or other biomass, has to be separated into lignine and cellulose. The cellulose is then used to make paper. The problem is that the two components are difficult to separate – the process still needs high pressures and temperatures, and it is costly to operate. Dissolving the wood chips has up to now not been an option because lignine is normally insoluble. But the new solvent, which Kroon has patented, makes this possible. As well as that the new solvent is entirely vegetable-based and biodegradable. Another advantage is that the new process produces very pure lignine, which the paper industry can use to develop new applications and markets such as making biodegradable plastics.

Paper production is energy-intensive, which is why the Dutch paper industry took the initiative in 2004 for its ‘Energy Transition Paper Chain 2004-2020’ plan which aims to halve energy consumption. The Confederation of European Paper industries (CEPI) is looking even further ahead, and intends to reduce CO2 emissions by 80% before 2050. The industry has therefore focused strongly on innovation for a number of years, using natural raw materials in a high-tech process. In its search for breakthrough technologies, CEPI organized a competition last year to find the best new ideas. The winner was the ‘deep eutectic solvents’ which Kroon had already been working on for several years. Henk van Houtum of the VNP expects that the solvent developed by Kroon will make a substantial contribution to meeting the industry’s energy targets. He hopes that the use of DES will lead to at least 40% lower energy costs and 20% less CO2 emissions.

TU/e signed a letter of intent last week with 14 European paper producers, including seven in the Netherlands, to continue development of the solvent. Kroon will use the funding from these companies to recruit two PhD candidates for a further four years of research at TU/e to prepare the way for the building of a pilot plant in the Netherlands. Kroon emphasizes that this is a very special agreement because it has been reached directly with the industrial companies, and does not rely on government financial support. It underlines the potential that the companies see in this development by the TU/e chemistry professor, and the importance they place on quickly implementing it in practice. Large-scale applications are expected to be possible in around 15 years. The laboratory research will take another five to ten years, with a similar period being required for optimization in the pilot plant.

Deep eutectic solvents were discovered in 2003 in the UK. They consist of a mixture of two compounds which, once they have been combined, have a much lower melting point than that of the individual components. Kroon believed that DES would make it possible to dissolve biomass, which formed the starting point for her present work. And it has indeed led to a process for dissolving lignine using different mixtures for specific types of wood.

Topics

Organizations

Other news from the department science

These products might interest you

ERBAdry by CARLO ERBA Reagents

Anhydrous solvents from CARLO ERBA Reagents in a clever redesign

ERBAdry series impresses with the latest generation of septa and sealing caps

Thermo Scientific™ Dionex™ ASE™ 150 or 350 Accelerated Solvent Extractor systems by Thermo Fisher Scientific

Accelerated Solvent Extraction (ASE) – Maximize results and reduce errors in food analysis!

More extractions in less time using less solvent

Get the chemical industry in your inbox

By submitting this form you agree that LUMITOS AG will send you the newsletter(s) selected above by email. Your data will not be passed on to third parties. Your data will be stored and processed in accordance with our data protection regulations. LUMITOS may contact you by email for the purpose of advertising or market and opinion surveys. You can revoke your consent at any time without giving reasons to LUMITOS AG, Ernst-Augustin-Str. 2, 12489 Berlin, Germany or by e-mail at revoke@lumitos.com with effect for the future. In addition, each email contains a link to unsubscribe from the corresponding newsletter.