Quicker method paves the way for atomic-level design

Advertisement

A new X-ray method will enable the development of more efficient catalysts. The method opens up new opportunities to work on atomic level in a number of areas of materials science. Researchers from Lund University are among those behind the new method.

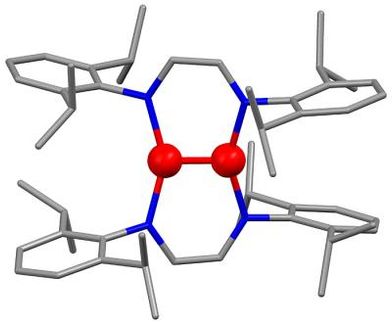

The new X-ray method is used to determine the atomic structure of the surface of different materials. The goal of the present research is to understand how catalysts work at atomic level – both the catalytic converters used for vehicle emissions control in cars and catalysts used in industry.

"Today, almost all developments in catalysts take place through a method of trial and error, but in order to be able to develop better catalysts in the future, deeper understanding of the atomic level is needed", says Dr Johan Gustafson, a researcher at the Department of Physics at Lund University.

A catalyst works by capturing the molecules that are to react on a catalytic surface. The effect of the surface on the molecules is to speed up the desired reaction. The surfaces of different materials capture and affect molecules in different ways. The new X-ray method offers researchers a significantly improved insight into what happens on these surfaces and in their active sites, i.e. the places where the molecules attach and react.

With this knowledge, the material in the catalyst can be optimised to speed up desired reactions and slow down others. The new X-ray method not only provides an instant picture of the situation on a surface, but can also be used to monitor changes over the time that the surface is subjected to different treatments.

"This could be a catalytic reaction that happens on the surface, as in our case. But it would also be possible to monitor how nanostructures grow or how metals oxidise, in conjunction with corrosion, as protection against corrosion or to change the properties of the surface in another way", says Johan Gustafson.

The researchers have developed the new X-ray method by using X-rays of around five times higher energy than usual. This means that a larger amount of data can be measured simultaneously, which in turn drastically reduces the time taken to conduct a full surface structure determination, from ten hours with the traditional method to roughly ten minutes with the new method.

Most read news

Organizations

Other news from the department science

Get the chemical industry in your inbox

By submitting this form you agree that LUMITOS AG will send you the newsletter(s) selected above by email. Your data will not be passed on to third parties. Your data will be stored and processed in accordance with our data protection regulations. LUMITOS may contact you by email for the purpose of advertising or market and opinion surveys. You can revoke your consent at any time without giving reasons to LUMITOS AG, Ernst-Augustin-Str. 2, 12489 Berlin, Germany or by e-mail at revoke@lumitos.com with effect for the future. In addition, each email contains a link to unsubscribe from the corresponding newsletter.