Frost & Sullivan recognizes BASF’s transformation

BASF showcases its multi-pronged success with a variety of interactive components and its own line of coatings

Based on its recent analysis of the European resins for protective coatings market, Frost & Sullivan recognizes BASF with the 2013 Product Line Strategy Leadership Award. The company has demonstrated strong growth by improving portfolio breadth, formulation expertise, and customer value to enhance its brand recognition. Simultaneously, it has undergone restructuring to enhance R&D and project management to align the company’s strategies with future goals.

BASF’s strategic acquisitions dramatically improved its coating raw materials portfolio and gave it access to many important technologies. This expanded portfolio has allowed the company to market itself as a provider of complete coatings solutions instead of just pure raw-material chemistry.

“The market continues to shift away from using high-solvent coatings, and BASF is leading this conversion by replacing alkyds with acrylic dispersions,” said Frost & Sullivan Industry Analyst Roland Heinze. “The company also looks to replace other conventional technologies to the greatest extent possible with similar competing and more sustainable ones in order to grow faster than the market.”

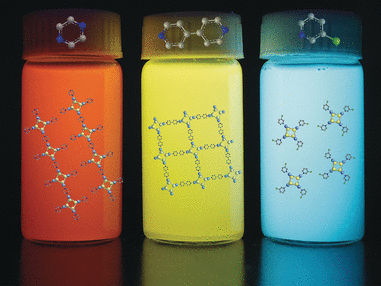

BASF’s portfolio now includes polyurethane, acrylic, melamine, and UV-curable resins, as well as light stabilizers, photo initiators, grinding resins, formulation additives, and pigments, all of which help the company fine tune product customization.

Although BASF’s competitors offer a broad range of coating resins, including epoxies, silicones, polyurethanes, and water-based acrylic dispersions, they do not provide equivalent formulation expertise in terms of combining resins, pigments, and additives. These companies also lack a presence in the downstream market, which BASF has successfully penetrated with its line of environmentally-friendly Acronal® and Joncryl® product lines.

This extensive portfolio of coating raw materials translates to a wide variety of applications including printing and packaging, furniture and flooring, automotive, transportation, wind power, pipelines, water treatment, agriculture and construction equipment, and direct-to-metal applications and composites.

BASF’s current approach to product portfolio development is based on market trends, which has increased the company’s brand recognition and new sales opportunities. A continuous stream of opportunities for new high-profile projects will continue to build BASF’s brand awareness and increase its market share in resins and additives that are not only used in protective coatings, but also in industries such as automotive, general industrial, furniture and flooring, and printing and packaging.

“BASF’s strategy is to focus on sustainability and work with many companies to learn more about the entire spectrum of raw materials,” noted Heinze. “It employs in-house experts to make sure that its additives are modified to function correctly, which, in turn, enables the company to rapidly move up the market ladder as a total solutions provider.”

Other news from the department business & finance

These products might interest you

OCA 200 by DataPhysics

Using contact angle meter to comprehensively characterise wetting behaviour, solids, and liquids

With its intuitive software and as a modular system, the OCA 200 answers to all customers’ needs

Tailor-made products for specific applications by IPC Process Center

Granulates and pellets - we develop and manufacture the perfect solution for you

Agglomeration of powders, pelletising of powders and fluids, coating with melts and polymers

Dursan by SilcoTek

Innovative coating revolutionizes LC analysis

Stainless steel components with the performance of PEEK - inert, robust and cost-effective

Get the chemical industry in your inbox

By submitting this form you agree that LUMITOS AG will send you the newsletter(s) selected above by email. Your data will not be passed on to third parties. Your data will be stored and processed in accordance with our data protection regulations. LUMITOS may contact you by email for the purpose of advertising or market and opinion surveys. You can revoke your consent at any time without giving reasons to LUMITOS AG, Ernst-Augustin-Str. 2, 12489 Berlin, Germany or by e-mail at revoke@lumitos.com with effect for the future. In addition, each email contains a link to unsubscribe from the corresponding newsletter.

Most read news

More news from our other portals

Last viewed contents

Boedeker_Plastics

Texize

Physicists capture first images of atomic spin

2-Butoxyethanol

Monte_Carlo_Universal

Intricate, curving 3D nanostructures for biological and materials applications

Measurement method for determining concentrations in dust deposition

Lipoxygenase

Atmospheric Measuring Device for Understanding Smog Formation - Quantitative assessment could lead to more effective smog-control strategies