Domain walls as new information storage medium

Visualization of domain wall motion: Material defects do not impede wall motion at high velocities

While searching for ever smaller devices that can be used as data storage systems and novel sensors, physicists at Johannes Gutenberg University Mainz (JGU) have directly observed magnetization dynamics processes in magnetic nanowires and thus paved the way for further research in the field of nanomagnetism. Small magnetic domain wall structures in nanowires can be used to store information and, for example, can be used as angle sensors. Initial applications based on magnetic domain walls have been developed and are already in use in sensor technology. The current findings represent the first experimentally recorded direct imaging of predicted correlations between magnetic spin structure and wall velocity. The newly discovered properties could be used for other future applications in information technology.

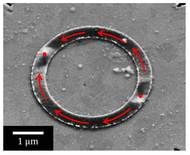

Image of a ferromagnetic ring prepared using a scanning electron microscope: The magnetization (black/white contrast) runs along the ring and forms two domain walls.

André Bisig

Magnetic domains represent regions of uniform magnetization in ferromagnetic materials. Within each domain, the magnetization is aligned in a single direction. At the interface where domains of different magnetization direction meet, the magnetization has to rotate from one direction to another in a so-called domain wall. At Mainz University, the group of Professor Mathias Kläui is studying the properties of magnetic domains and the dynamics of domains and domain walls in tiny rings on the nanoscale. It is possible to directly observe the motion of domain walls in these rings that have a diameter of some 4 micrometers and are made of permalloy, a soft nickel-iron alloy. For this purpose, the Mainz physicists have been collaborating with scientists of the BESSY II synchrotron facility at the Helmholtz Center Berlin for Materials and Energy and the Advanced Light Source (ALS) at the Lawrence Berkeley National Laboratory, Berkeley, USA, as well as with the Technical University of Berlin and the Max Planck Institute for Intelligent Systems in Stuttgart.

The researchers discovered that the velocity of the motion of domain walls is always oscillating. "This is a new effect that could prove to be useful in the future," said Dr. André Bisig, lead author of the paper "Correlation between spin structure oscillations and domain wall velocities," which has recently been published in Nature Communications. It was also found that the applied method is very effective in reliably moving the domain walls at very high velocities. "The faster we move the domain wall, the easier it is to control it," said Bisig. Another observation concerns the effects associated with irregularities or defects in the nanowires. According to the results, these effects only become noticeable when domain walls are moving slowly. The faster a domain wall spins, the less relevant is the role played by defects in the material.

While theoretical research concerns itself principally with observing domain wall velocity and its correlation with oscillations in the spin structure, the results obtained also have important implications for applied research. Domain wall-based sensors are already being used by Sensitec GmbH, Mainz, a cooperating partner of JGU and the Technical University of Kaiserslautern in two projects funded by the state of Rhineland-Palatinate: the Spintronics Technology Platform in Rhineland-Palatinate (STeP) and the Technology Transfer Service Center for New Materials (TT-DINEMA). "Of particular importance is the fact that we observed unimpeded domain wall motion at high domain wall velocities. This represents highly promising potential for the use of these nanostructures in ultra-fast rotating sensors," added Professor Mathias Kläui. The research being undertaken by Professor Kläui's team is being funded by an ERC Starting Grant and the Graduate School of Excellence Materials Science in Mainz (MAINZ). In addition, cooperation with Sensitec has resulted in access to a joint EU project involving seven other leading partners expected to start in October 2013 on "Controlling domain wall dynamics for functional devices".

Original publication

A. Bisig et al., Correlation between spin structure oscillations and domain wall velocities, Nature Communications, 4:2328, 27. August 2013

Other news from the department science

These products might interest you

Most read news

More news from our other portals

See the theme worlds for related content

Topic world Sensor technology

Sensor technology has revolutionized the chemical industry by providing accurate, timely and reliable data across a wide range of processes. From monitoring critical parameters in production lines to early detection of potential malfunctions or hazards, sensors are the silent sentinels that ensure quality, efficiency and safety.

Topic world Sensor technology

Sensor technology has revolutionized the chemical industry by providing accurate, timely and reliable data across a wide range of processes. From monitoring critical parameters in production lines to early detection of potential malfunctions or hazards, sensors are the silent sentinels that ensure quality, efficiency and safety.