Ytterbium atomic clocks set record for stability

Advertisement

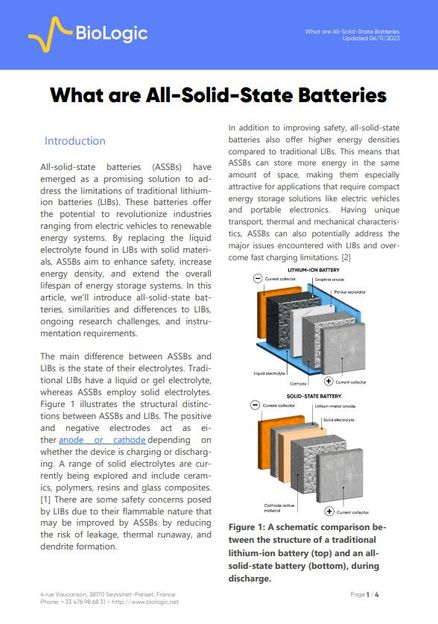

A pair of experimental atomic clocks based on ytterbium atoms at the National Institute of Standards and Technology (NIST) has set a new record for stability. The clocks act like 21st-century pendulums or metronomes that could swing back and forth with perfect timing for a period comparable to the age of the universe.

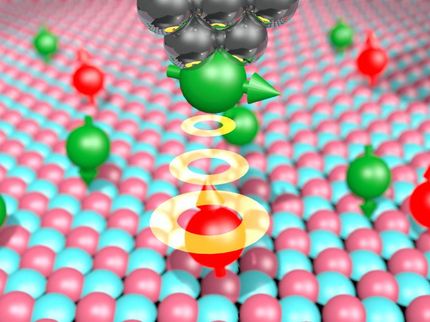

In NIST's ultra-stable ytterbium lattice atomic clock, ytterbium atoms are generated in an oven (large metal cylinder on the left) and sent to a vacuum chamber in the center of the photo to be manipulated and probed by lasers. Laser light is transported to the clock by five fibers (such as the yellow fiber in the lower center of the photo).

Burrus/NIST

NIST physicists report in issue of Science Express that the ytterbium clocks' tick is more stable than any other atomic clock. Stability can be thought of as how precisely the duration of each tick matches every other tick. The ytterbium clock ticks are stable to within less than two parts in 1 quintillion (1 followed by 18 zeros), roughly 10 times better than the previous best published results for other atomic clocks.

This dramatic breakthrough has the potential for significant impacts not only on timekeeping, but also on a broad range of sensors measuring quantities that have tiny effects on the ticking rate of atomic clocks, including gravity, magnetic fields, and temperature. And it is a major step in the evolution of next-generation atomic clocks under development worldwide, including at NIST and at JILA, the joint research institute operated by NIST and the University of Colorado Boulder.

"The stability of the ytterbium lattice clocks opens the door to a number of exciting practical applications of high-performance timekeeping," NIST physicist and co-author Andrew Ludlow says.

Each of NIST's ytterbium clocks relies on about 10,000 rare-earth atoms cooled to 10 microkelvin (10 millionths of a degree above absolute zero) and trapped in an optical lattice—a series of pancake-shaped wells made of laser light. Another laser that "ticks" 518 trillion times per second provokes a transition between two energy levels in the atoms. The large number of atoms is key to the clocks' high stability.

The ticks of any atomic clock must be averaged for some period to provide the best results. One key benefit of the very high stability of the ytterbium clocks is that precise results can be achieved very quickly. For example, the current U.S. civilian time standard, the NIST-F1 cesium fountain clock, must be averaged for about 400,000 seconds (about five days) to achieve its best performance. The new ytterbium clocks achieve that same result in about one second of averaging time.

Given this high level of stability the ytterbium clocks can make measurements extremely rapidly—in real time in many cases—which could be important in rapidly changing application settings, such as the factory floor and the natural environment.

A key advance enabling the milestone performance of the ytterbium clocks was the recent construction of a second version of the clock to measure and improve the performance of the original, developed since 2003. Along the way, NIST scientists have made several improvements to both clocks, including the development of an ultra-low-noise laser used to excite the atoms, and the discovery of a method to cancel disruptive effects caused by collisions between atoms.

The ytterbium clocks' stability record is different from the performance levels previously publicized for NIST-F1, which is traceable to the international system of units, and NIST experimental optical clocks based on single ions, such as the aluminum quantum logic clock or the mercury ion clock. NIST-F1 and the ion clocks were evaluated based on systematic uncertainty, another important metric for standard atomic clocks. NIST-F1's performance is described in terms of accuracy, which refers to how closely the clock realizes the cesium atom's known frequency, or natural vibration rate. Accuracy is crucial for time measurements that must be traced to a primary standard.

Other news from the department science

These products might interest you

Most read news

More news from our other portals

See the theme worlds for related content

Topic world Sensor technology

Sensor technology has revolutionized the chemical industry by providing accurate, timely and reliable data across a wide range of processes. From monitoring critical parameters in production lines to early detection of potential malfunctions or hazards, sensors are the silent sentinels that ensure quality, efficiency and safety.

Topic world Sensor technology

Sensor technology has revolutionized the chemical industry by providing accurate, timely and reliable data across a wide range of processes. From monitoring critical parameters in production lines to early detection of potential malfunctions or hazards, sensors are the silent sentinels that ensure quality, efficiency and safety.