Hydrogen cars quickened by Copenhagen chemists

Green cars

Advertisement

Climate friendly fuel cells for hydrogen cars have come one step closer. Researchers at the Department of Chemistry, University of Copenhagen, have shown how to build fuel cells that produce as much electricity as current models, but require markedly less of the rare and valuable precious metal platinum. Their discovery was published in the highly reputable periodical Nature Materials.

Cheaper hydrogen cars with new fuel cell design

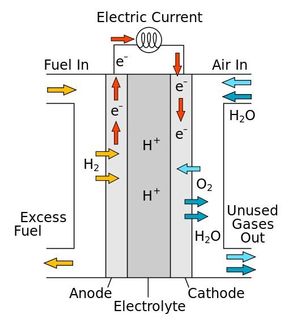

Fuel cells ought to replace internal combustion engines in our cars. They are better for the climate and for the environment. Partly because fuel cells use the fuel much more efficiently. Partly because they emit no smoke, no smog, no CO2.

Unfortunately the fuel cells have a technical limitation. They only work if they contain the metal platinum which is less common and more costly than gold. This has been a considerable obstacle to the development of the energy efficient power generators.

Reduced need for metal increases economic yield

Matthias Arenz is an associate professor at the Department of Chemistry, University of Copenhagen. In collaboration with researchers from the Technical University München and the Max Planck Institute for Iron Research in Düsseldorf he has built and tested a number of catalysts, the devices at the heart of a fuel cell. Arenz is confident that his discovery can show the way for economically viable fuel cell production.

"In the lab we have shown, that we can generate the same amount of electricity with just a fifth of the platinum. We don’t expect to do quite that well in an everyday situation, but a marked reduction in platinum need is certainly realistic. And that will be a huge financial advantage."

One of the most costly elements

The precious metal platinum is one of the rarest elements on earth. Most of it is to be found in South Africa, where 80 percent of world production is mined while Russia extracts another ten percent. This means that the metal is strategically important.

In 2012 world production was 179 metric tons. By comparison gold production was 2.700 tons. And while the cost of platinum in 2010 was 1.600 dollars per Troy Ounce gold sold at just 1.300 dollars for a Troy Ounce.

Sheets, particles or nanoparticles

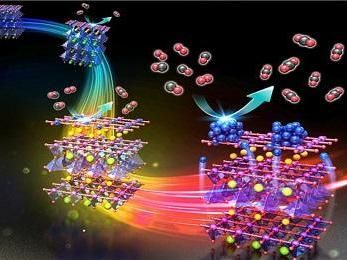

Fuel cells produce electricity from hydrogen and oxygen in a so called catalytic reaction which is kept going by platinum. The greatest effect is achieved by flowing your gasses over a sheet or film of platinum but that requires large amounts of the costly element. Instead modern fuel cells are made with particles, little granules, of platinum. What the research in Arenz’ group showed was, that these granules could be placed more efficiently.

Five times more electricity for every gram of metal

When tested in the laboratory, catalysts bought on the market today will produce around one Ampere for every milligram of metal. The Arenz group developed a fuel cell catalyst that got a whopping eight Ampere per milligram of platinum. Their initial instinct was that they got a bigger power yield, because they had used smaller granules of platinum. But careful measurement revealed something much more surprising.

Unexpected effect discovered by chance

The key factor leading to platinum savings might never have been discovered by the group. They had produced a number of catalysts with varying sizes of platinum particles. By chance the particles were very tightly packed on a few of the sample catalysts and as it turned out, the packing of the particles was much more significant than the size. An effect, that the researchers have dubbed the “Particle Proximity Effect”.

Next step will be to develop a chemical method to produce tightly packed catalysts on an industrial scale. Arenz has a few ideas for that as well, so he and his group have started applying for grants.