Cool it, quick: Rapid cooling leads to stronger alloys

Researchers reveal a new technique to produce high strength metallic alloys, at a lower cost using less energy

Advertisement

A team of researchers from the University of Rostock in Germany has developed a new way to rapidly produce high strength metallic alloys, at a lower cost using less energy than before. It's expected that this breakthrough will profoundly change how we produce components used in a diverse range of applications; including transport and medical devices.

The research, which appears in the latest issue of the open access journal Materials Today, reports on the first Spark Plasma Sintering (SPS) system with an integrated gas quenching mechanism, capable of alternating the phase compositions and retaining the smallest grain features inside a structured metallic alloy.

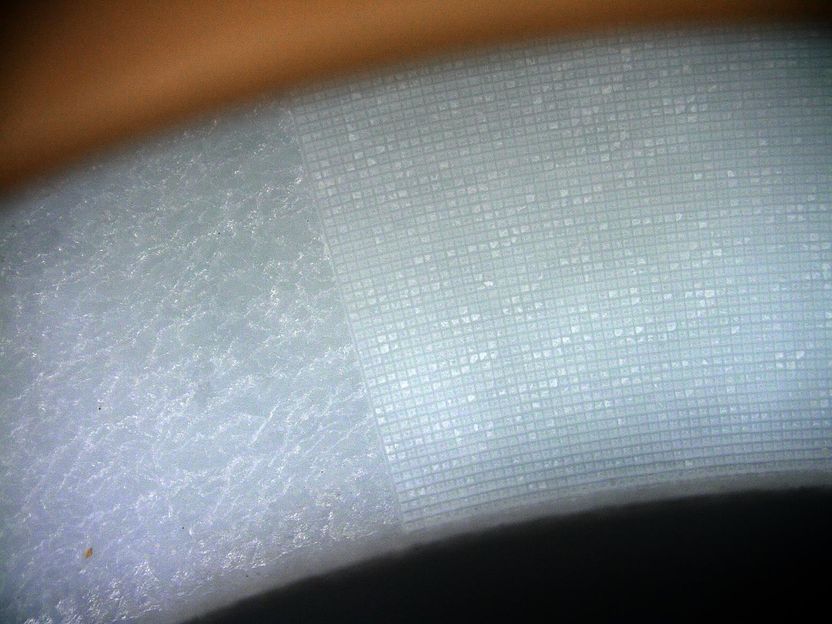

SPS is a technique used to fuse fine powders into a dense solid material, by placing powder into a mold (or die) and simultaneously applying pulses of electric current and mechanical pressure to it. By varying SPS cooling rates, it is possible to control the phase and grain sizes in a material, and so, to tune its mechanical properties. In their study, the team of researchers led by Dr. Eberhard Burkel, a Professor of Physics of New Materials, demonstrated that rapidly cooling a material directly after SPS fabrication can produce a material with enhanced hardness, strength and ductility.

The new rapid cooling SPS system is based on a commercially available design, modified to include a series of gas inlet nozzles. After sintering, most SPS systems are left to cool naturally, or are flooded with argon gas. The system blasts nitrogen gas into the chamber at high speeds, rapidly cooling the material.

To demonstrate the utility of the system, Grade 5 Titanium (Ti-6Al-4V) – known as the "workhorse" of the titanium industry – was produced at different cooling rates. The most-rapidly cooled alloy was found to be up to 12% harder than the naturally-cooled alloy, and with an improved ductility up to 34±3%. Ti-6Al-4V is the most common titanium alloy in use worldwide, with applications in the aerospace, biomedical and marine industries.

In their article the researchers explain, "This high-ductile alloy offers unprecedented opportunities for the easy manufacturing of complex shapes for biomedical and new engineering applications."

First author of the study, Dr. Faming Zhang, said "The system will play a major role in the production of novel materials, from metals, alloys, metal matrix composites to micro- and nanostructured semiconductors."

Most read news

Other news from the department science

Get the chemical industry in your inbox

By submitting this form you agree that LUMITOS AG will send you the newsletter(s) selected above by email. Your data will not be passed on to third parties. Your data will be stored and processed in accordance with our data protection regulations. LUMITOS may contact you by email for the purpose of advertising or market and opinion surveys. You can revoke your consent at any time without giving reasons to LUMITOS AG, Ernst-Augustin-Str. 2, 12489 Berlin, Germany or by e-mail at revoke@lumitos.com with effect for the future. In addition, each email contains a link to unsubscribe from the corresponding newsletter.