Sieving silica sieves from biomass ash

Advertisement

Burning biomass for heat and power could produce as much as 2000 TWh by 2020, which would produce 4–15.6 million tonnes of waste ash, per year, in Europe alone. To address the problem of what to do with all this waste, scientists in the UK have developed a method to convert this ash into mesoporous silica.

Although some of the waste ash produced from the combustion of biomass is currently used in construction, most of it ends up in landfill. Therefore, extracting alkali silicates, which can be used in cement, detergents, catalysts and catalyst supports, is one way of reusing the potentially huge quantities of ash due to be produced in the future.

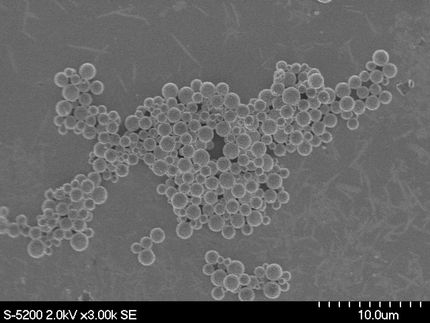

The team, led by Duncan Maquarrie at the University of York, developed an efficient route for extracting the silicates by forming alkali silicate solutions. The silicate solutions were converted into the porous silica, MCM-41, a useful catalyst and molecular sieve.

Other news from the department science

Get the chemical industry in your inbox

By submitting this form you agree that LUMITOS AG will send you the newsletter(s) selected above by email. Your data will not be passed on to third parties. Your data will be stored and processed in accordance with our data protection regulations. LUMITOS may contact you by email for the purpose of advertising or market and opinion surveys. You can revoke your consent at any time without giving reasons to LUMITOS AG, Ernst-Augustin-Str. 2, 12489 Berlin, Germany or by e-mail at revoke@lumitos.com with effect for the future. In addition, each email contains a link to unsubscribe from the corresponding newsletter.