Making temperature-sensitive porous nanolayers

A method of manufacturing porous nanolayers using temperature-sensitive substrates has been developed by scientists.

Traditionally such materials are made using flame spray pyrolysis (FSP), but this process is limited by the thermal sensitivity of the substrate onto which the nanoparticles are coated. Furthermore the mechanical stability of the layers is often weak in liquid environments.

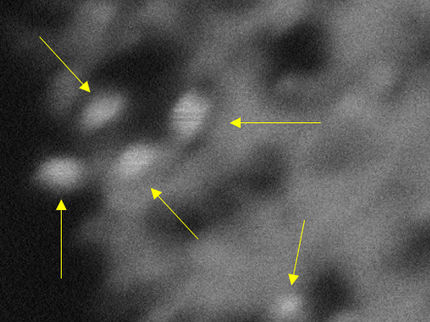

The new process involves separating the pyrolysis step from the introduction of the final substrate material. In stage one the nanoparticles (e.g. titanium dioxide) are coated onto an initial substrate, using FSP, to create an intermediate porous nanolayer material. In stage two a new substrate is applied to the intermediate material to create a ‘nanoparticle sandwich’, which is passed through rollers under pressure and at low temperature. The nanoparticle layer transfers to the new substrate to yield the final material.

The technique produces materials that have superior mechanical stability, and opens up the possibility of using different substrates, such as polypropylene foil.

Other news from the department science

These products might interest you

NANOPHOX CS by Sympatec

Particle size analysis in the nano range: Analyzing high concentrations with ease

Reliable results without time-consuming sample preparation

Eclipse by Wyatt Technology

FFF-MALS system for separation and characterization of macromolecules and nanoparticles

The latest and most innovative FFF system designed for highest usability, robustness and data quality

DynaPro Plate Reader III by Wyatt Technology

Screening of biopharmaceuticals and proteins with high-throughput dynamic light scattering (DLS)

Efficiently characterize your sample quality and stability from lead discovery to quality control

Get the chemical industry in your inbox

By submitting this form you agree that LUMITOS AG will send you the newsletter(s) selected above by email. Your data will not be passed on to third parties. Your data will be stored and processed in accordance with our data protection regulations. LUMITOS may contact you by email for the purpose of advertising or market and opinion surveys. You can revoke your consent at any time without giving reasons to LUMITOS AG, Ernst-Augustin-Str. 2, 12489 Berlin, Germany or by e-mail at revoke@lumitos.com with effect for the future. In addition, each email contains a link to unsubscribe from the corresponding newsletter.