Painting with catalysts

Nano-engineered materials for detoxifying water by use of sunlight

Advertisement

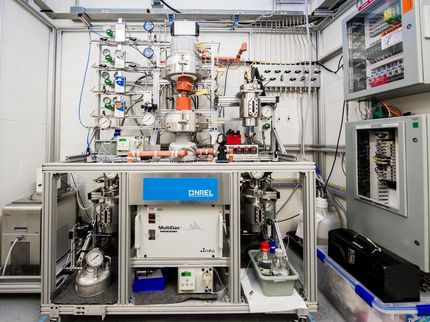

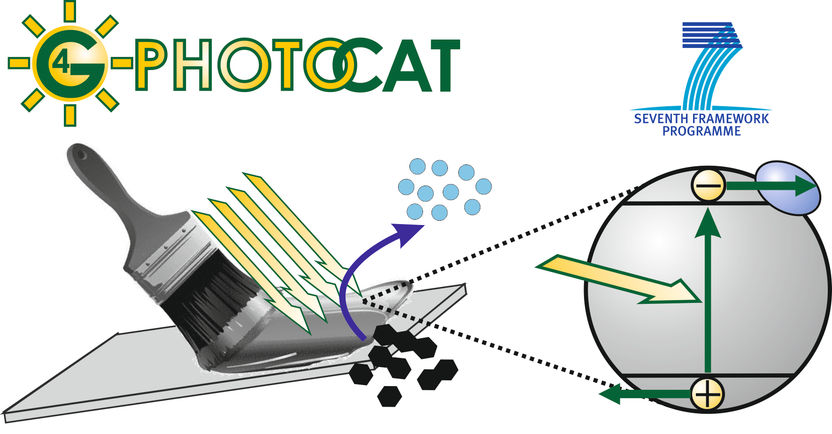

Only light, aerial oxygen, and a catalyst are needed to remove pollutants from water. RUB researchers led by Prof. Radim Beránek collaborate with colleagues from seven different countries in order to develop a photocatalyst that is efficient enough to be profitable. For that purpose, they combine sunlight-absorbing semiconductors and nanostructured materials which they optimize for electron transfer processes. The aim is to implement the newly developed photocatalysts into a liquid paint with which photoreactors can easily be coated. The EU supports the project within its 7th Framework Programme (FP7) with 3.7 million Euro funding for three years.

Catalysts for painting: Together with their international colleagues, RUB researchers develop catalysts that detoxify water with the aid of sunlight and aerial oxygen. They aim to fabricate the catalysts as a liquid paint.

© Radim Beránek

Current problems of photocatalysis

People from many countries of the world extensively use pesticides which contaminate drinking and irrigation water with toxic organic compounds. In rural areas of Vietnam, herbicides and dioxins, resistant to degradation, made their way into the water cycle during the Vietnam war. Cancer and abnormalities in newborns can be the consequence. “Photocatalysis is potentially one of the cheapest and most efficient methods for purifying water from pollutants,” Radim Beránek says. Sunlight and oxygen establish oxidizing conditions under which toxins are easily degraded into non-harmful substances like water and carbon dioxide. Up to now the process, however, faces two problems: degradation rates are too low and assembly of the needed photoreactors is too expensive.

The aim: cheeper and more efficient catalysts

Within the project “4G-PHOTOCAT”, the researchers aim to develop cost-efficient photocatalysts with a considerably improved degradation rate. Therefore they fabricate innovative composite materials consisting of semiconductors and nanostructured metal oxides. In order to achieve the optimal architecture for the product, they employ advanced chemical deposition techniques with a high degree of control over composition and morphology. “Our ultimate goal is to implement the newly developed photocatalysts into a liquid paint,” Radim Beránek says. “Photoreactors painted with that liquid can be used, for example, for water decontamination in remote rural areas of Vietnam.”

Collaborators

“4G-PHOTOCAT “allies the expertise of seven academic and three industrial partners from five European countries and two Southeast Asian countries. At the RUB, Prof. Dr. Radim Beránek collaborates with Prof. Dr. Roland A. Fischer (Inorganic Chemistry II), Prof. Dr. Martin Muhler, and Dr. Jennifer Strunk (Industrial Chemistry). The international collaborators include scientists from the University College London, J. Heyrovský Institute of Physical Chemistry in Prague, Jagiellonian University Krakow, University of Helsinki, Universiti Teknologi Malaysia, and Hanoi University of Agriculture. Furthermore, industrial partners from Finland (Picosun), Czech Republic (Advanced Materials), and Vietnam (Q&A) have joined the team.