A new technology for producing hydrogen

Aingeru Remiro has developed a process to obtain hydrogen from bio-oil

Advertisement

The Ph.D. thesis of Aingeru Remiro-Eguskiza, a chemical engineer of the University of the Basque Country, deals with the quest for a process to produce hydrogen from bio-oil that has a lower impact on the environment than the process using current routes.

This is Aingeru Remiro-Eguskiza, Ph.D. holder in Chemical Engineering from the UPV/EHU.

UPV/EHU

The gradual increase in the price of crude oil and the negative environmental consequences that its use entails are putting us on the threshold of a change of energy model that will need to be tackled over the coming decades. Faced with the obvious necessity of finding an energy alternative that will replace fossil fuels in the near future at least partially and in a gradual way, hydrogen is emerging as one of the alternatives.

Currently, hydrogen is obtained through various methods that require separating the hydrogen from other chemical elements like carbon (in fossil fuels) and oxygen (from water). The methods used for this purpose are not viable from an environmental or economic perspective, respectively, as far as the large-scale production of hydrogen is concerned.

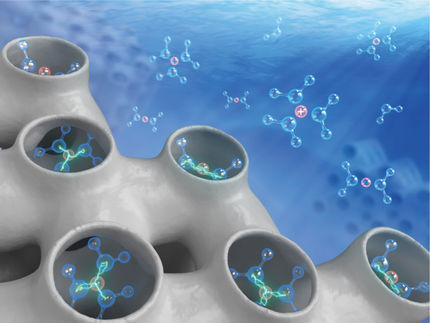

The aim of this thesis was to contribute towards the laboratory scale development of a process for producing hydrogen from bio-oil by means of catalytic reforming using water vapour. Bio-oil is a heterogeneous mixture of wood-based oxygenated products, the catalytic transformation of which routinely entails problems of operability and deactivation of the catalyst. This is because when it is being heated, a fraction of the compounds that make up the bio-oil form a solid residue (the so-called pyrolytic lignin) which collects on the inlet pipes of the reactor and in the reactor itself. The bio-oil used for the research in the thesis was developed at an IK4-Ikerlan plant.

An in-house designed reaction unit

To solve the problems caused by the use of bio-oil, an in-house designed reaction unit was used and which comprises two stages: the thermal and the catalytic stages. In the thermal stage (in which the bio-oil is heated) the controlled deposition of the pyrolytic lignin takes place and this minimizes the operational problems and the deactivation of the catalyst. That way the compounds obtained in the thermal stage are more susceptible to being transformed.

In addition, a third stage has been incorporated into the process: the CO2 capture intended to intensify the production of H2 increases its purity and cuts the associated contaminating emissions. The process involves using an adsorber in the reaction bed and which is designed to capture the CO2. "When the CO2 is eliminated from the reaction bed, we are encouraging the displacement of the reaction equilibriums and, as a result, a greater yield and a greater output of hydrogen are obtained," explains Remiro.

In this context, he stresses that improvement in the CO2 capture in the reaction bed was verified when extremely pure hydrogen, close to 100%, was obtained and at a lower operating temperature with respect to the process minus the CO2 capture.