Nanoparticles digging the world’s smallest tunnels

The world’s smallest tunnels have a width of a few nanometers only. Researchers from Karlsruhe Institute of Technology (KIT) and Rice University, USA, have dug such tunnels into Graphite samples. This will allow structuring of the interior of materials through self-organization in the nanometer range and tailoring of nanoporous graphite for applications in medicine and battery technology. Results are now presented in Nature Communications.

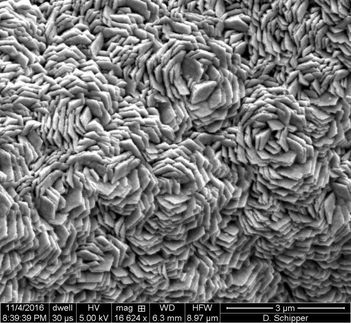

The tunnels are manufactured applying nickel nanoparticles to graphite which then is heated in the presence of hydrogen gas. The surface of the metal particles, that measure a few nanometers only, serves as a catalyst removing the carbon atoms of the graphite and converting them by means of hydrogen into the gas methane. Through capillary forces, the nickel particle is drawn into the “hole” that forms and bores through the material. The size of the tunnels obtained in the experiments was in the range of 1 to 50 nanometers, which about corresponds to one thousandth of the diameter of a human hair.

To furnish proof of the real existence of these graphite tunnels, the researchers have made use of scanning electron and scanning tunneling microscopy. “Microscopes, in fact, image only the upper layers of the sample,” the principal authors of the study, Maya Lukas and Velimir Meded from KIT’s Institute of Nanotechnology, explain. “The tunnels below these upper layers, however, leave atomic structures on the surface whose courses can be traced and which can be assigned to the nanotunnels by means of the very detailed scanning tunneling microscopy images and based on computerized simulations.” In addition, the depth of the tunnels was determined precisely by means of a series of images taken by a scanning electron microscope from different perspectives.

Porous graphite is used, for example, in the electrodes of lithium ion batteries. The charge time could be reduced using materials with appropriate pore sizes. In medicine, porous graphite could serve as a carrier of drugs to be released over longer periods of time. Replacing graphite by nonconductive materials, e.g. boron nitride, with atomic structures similar to that of graphite, the tunnels could serve as basic structures for nanoelectronic components such as novel sensors or solar cells.

Other news from the department science

These products might interest you

NANOPHOX CS by Sympatec

Particle size analysis in the nano range: Analyzing high concentrations with ease

Reliable results without time-consuming sample preparation

Eclipse by Wyatt Technology

FFF-MALS system for separation and characterization of macromolecules and nanoparticles

The latest and most innovative FFF system designed for highest usability, robustness and data quality

DynaPro Plate Reader III by Wyatt Technology

Screening of biopharmaceuticals and proteins with high-throughput dynamic light scattering (DLS)

Efficiently characterize your sample quality and stability from lead discovery to quality control

Get the chemical industry in your inbox

By submitting this form you agree that LUMITOS AG will send you the newsletter(s) selected above by email. Your data will not be passed on to third parties. Your data will be stored and processed in accordance with our data protection regulations. LUMITOS may contact you by email for the purpose of advertising or market and opinion surveys. You can revoke your consent at any time without giving reasons to LUMITOS AG, Ernst-Augustin-Str. 2, 12489 Berlin, Germany or by e-mail at revoke@lumitos.com with effect for the future. In addition, each email contains a link to unsubscribe from the corresponding newsletter.