Toughened silicon sponges may make tenacious batteries

Rice University, Lockheed Martin researchers extract multiple anodes from a single wafer for lithium-ion batteries

Researchers at Rice University and Lockheed Martin reported that they've found a way to make multiple high-performance anodes from a single silicon wafer. The process uses simple silicon to replace graphite as an element in rechargeable lithium-ion batteries, laying the groundwork for longer-lasting, more powerful batteries for such applications as commercial electronics and electric vehicles.

The work led by Sibani Lisa Biswal, an assistant professor of chemical and biomolecular engineering at Rice, and lead author Madhuri Thakur, a Rice research scientist, details the process by which Swiss cheese-like silicon "sponges" that store more than four times their weight in lithium can be electrochemically lifted off of wafers. The research was reported online in the American Chemical Society journal Chemistry of Materials.

Silicon – one of the most common elements on Earth – is a candidate to replace graphite as the anode in batteries. In a previous advance by Biswal and her team, porous silicon was found to soak up 10 times more lithium than graphite.

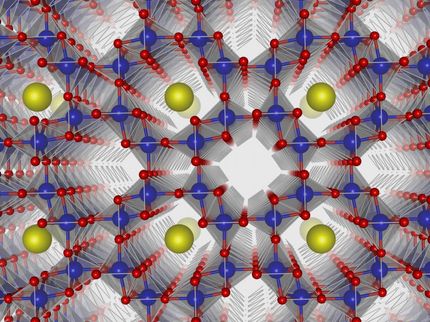

Because silicon expands as it absorbs lithium ions, the sponge-like configuration gives it room to grow internally without degrading the battery's performance, the researchers reported. The promise that silicon sponges, with pores a micron wide and 12 microns deep, held for batteries was revealed in 2010 at Rice's Buckyball Discovery Conference by Thakur, Biswal, their Rice colleague Michael Wong, a professor of chemical and biomolecular engineering and of chemistry, and Steven Sinsabaugh, a Lockheed Martin Fellow. But even then Thakur saw room for improvement as the solid silicon substrate served no purpose in absorbing lithium.

In the new work, they discovered the electrochemical etching process used to create the pores can also separate the sponge from the substrate, which is then reused to make more sponges. The team noted that at least four films can be drawn from a standard 250-micron-thick wafer. Removing the sponge from the silicon substrate also eliminates a limiting factor to the amount of lithium that can be stored.

The team also found a way to make the pores 50 microns deep. Once lifted from the wafer, the sponges, now open at the top and bottom, were enhanced for conductivity by soaking them in a conductive polymer binder, pyrolyzed polyacrylonitrile (PAN).

The product was a tough film that could be attached to a current collector (in this case, a thin layer of titanium on copper) and placed in a battery configuration. The result was a working lithium-ion battery with a discharge capacity of 1,260 milliamp-hours per gram, a capability that should lead to batteries that last longer between charges.

The researchers compared batteries using their film before and after the PAN-and-bake treatment. Before, the batteries started with a discharge capacity of 757 milliamp-hours per gram, dropped rapidly after the second charge-discharge cycle and failed completely by cycle 15. The treated film increased in discharge capacity over the first four cycles – typical for porous silicon, the researchers said – and the capacity remained consistent through 20 cycles.

The researchers are investigating techniques that promise to vastly increase the number of charge-discharge cycles, a critical feature for commercial applications in which rechargeable batteries are expected to last for years.

Other news from the department science

Most read news

More news from our other portals

See the theme worlds for related content

Topic World Battery Technology

The topic world Battery Technology combines relevant knowledge in a unique way. Here you will find everything about suppliers and their products, webinars, white papers, catalogs and brochures.

Topic World Battery Technology

The topic world Battery Technology combines relevant knowledge in a unique way. Here you will find everything about suppliers and their products, webinars, white papers, catalogs and brochures.