Bayer MaterialScience awards brand and distribution license to Solid Composites

Advertisement

Bayer MaterialScience and Solid Composites GmbH are partnering to develop thermoplastic polyurethane (TPU) powders for selective laser sintering. This method for fabricating three-dimensional structures is based on the use of a laser beam to sinter powdered starting materials. The start-up company based in Voerde, on the Lower Rhine, will be awarded a brand license to market the new high-tech materials under the name Desmosint. This opens the door to numerous potential applications, for instance in the automotive industry, in sports goods, robotics or aerospace engineering. Solid Composites is a spin-off of the Fraunhofer Institute for Environmental, Safety and Energy Technology (UMSICHT).

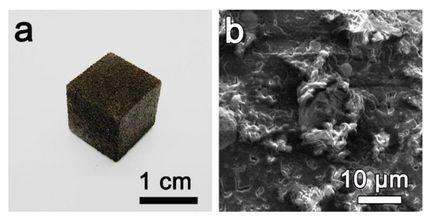

Bayer MaterialScience and Solid Composites GmbH are partnering to develop ther-moplastic polyurethane (TPU) powders for selective laser sintering. This innovative method for fabricating three-dimensional structures is based on the use of a laser beam to sinter powdered starting materials. A part is made from a thermoplastic powder based on the part’s structural design data. Guided by CAD software, a laser fuses successive layers of a powder bed at selected points where the part is to emerge. In other words, the part “grows” layer by layer.

Fraunhofer Institut für Umwelt-, Sicherheits- und Energietechnik (UMSICHT)

“Solid Composites has made a name for itself as a creative developer and supplier of thermoplastic powders for laser sintering and electrostatic coating, among other things, and is therefore the partner of choice for us when it comes to successfully marketing our TPU innovation,” explains Jürgen Hättig, TPU marketing specialist at Bayer MaterialScience.

No molds necessary

Selective laser sintering is becoming a firmly established digital manufacturing method in the additive manufacturing of plastic parts. A part is made from a thermoplastic powder based on the part’s structural design data. Guided by CAD software, a laser fuses successive layers of a powder bed at selected points where the part is to emerge. In other words, the part “grows” layer by layer. “The method eliminates the use of molds, and that cuts costs considerably. Furthermore, in contrast to injection molding, even parts having complex geometries with cavities and undercuts can be rendered,” explains Marcus Rechberger, general manager of Solid Composites.

Material gap closed

Until now, primarily soft, elastic materials and rigid thermoplastics, such as polyamide, were commercially available for selective laser sintering. “Our TPU products, with their high toughness, elasticity and strength, have now closed the gap between these material classes. And that opens the door to good application opportunities,” Hättig says.