Singapore-made Anti-reflective Plastics to be Commercialised

Researchers from A*STAR's Institute of Materials Research and Engineering (IMRE) and their commercial partners have developed a new plastic that reflects just 0.09 - 0.2% of the visible light hitting its surface. This matches or betters existing anti-reflective and anti-glare plastics in the market, which typically have reported reflectivity of around 1% of visible light. Such plastics are used in anything from TV displays to windows and even solar cells. Because of the unique nanotechnology method used, the new plastic developed by IMRE maintains very low reflectivity (<0.7%) at angles up to 45 degrees. This means that TV viewers can have wider viewing angles with less glare and organic solar cells have larger areas for light absorption.

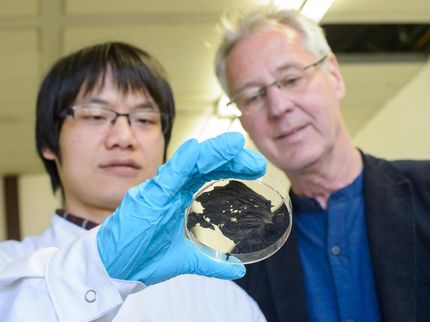

"The new plastic was made possible because of the unique nanoimprint expertise that we have developed at IMRE," said Dr Low Hong Yee, the senior scientist who is leading the research. Several companies are in the process of licensing the anti-reflective nanostructure technology from Exploit Technologies Pte Ltd, the technology transfer arm of A*STAR. "We are also developing complementary research that allows the technology to be easily ramped-up to an industrial scale," explained Dr Low.

This plastic material is the first successful result of the IMRE-led Industrial Consortium On Nanoimprint (ICON), which partners local and overseas companies to promote the manufacturing of nanoimprint technology. Nanoimprinting relies on engineeringthe physical aspects of the plastics rather than using harmful chemicals to change the properties of the plastic. The technology has allowed the researchers to create very unique, complex hierarchical 'moth eye-like' anti-reflective structures wherenanometer-sized structures are placed on top of other microstructures - different from how other similar plastics are made. This formed special patterns that are better at reducing glare and reflection and provides wider viewing angles than the currentavailable plastics.

Most read news

Other news from the department research and development

Get the chemical industry in your inbox

By submitting this form you agree that LUMITOS AG will send you the newsletter(s) selected above by email. Your data will not be passed on to third parties. Your data will be stored and processed in accordance with our data protection regulations. LUMITOS may contact you by email for the purpose of advertising or market and opinion surveys. You can revoke your consent at any time without giving reasons to LUMITOS AG, Ernst-Augustin-Str. 2, 12489 Berlin, Germany or by e-mail at revoke@lumitos.com with effect for the future. In addition, each email contains a link to unsubscribe from the corresponding newsletter.