Atomic Layer Deposition (ALD) to enable novel, high efficiency silicon nanorod solar cells

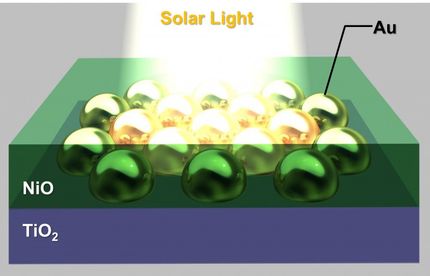

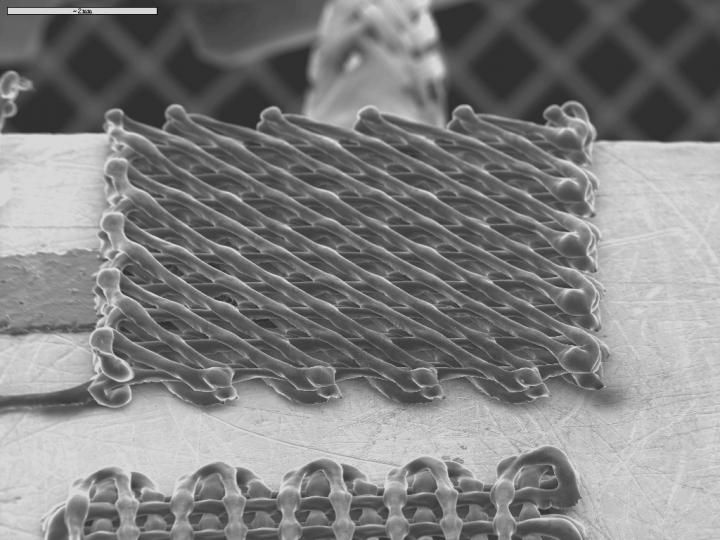

Picosun Oy reports successful final results of the European Union 7th Framework Programme funded research project ROD-SOL. The goal of this multinational, inter-European, three years (2009-2011) project combining the efforts of both scientific and industrial partners has been to dramatically increase the efficiency of solar cells and reduce the costs of their manufacturing. This has been achieved with novel, innovative, silicon nanorod based concept. The amount of active photovoltaic material (Si) can be significantly reduced by growing the light-trapping nanorod “forests” (thickness from < 1μm to a few μm at most) on cheaper substrates such as glass or flexible foils. This has led to already promising over 9% energy conversion efficiencies with very good long-term stabilities of cells. Due to their effectively 3D geometry, the nanorod forests have high active surface area which enables efficient light absorption – much more efficient than in convenient 2D thin film solar cells. Also, the location of the p-n junction much closer to the surface than in normal solar cells radically improves the minority carrier charge transport and thus the amount of electricity that can be extracted from the cell.

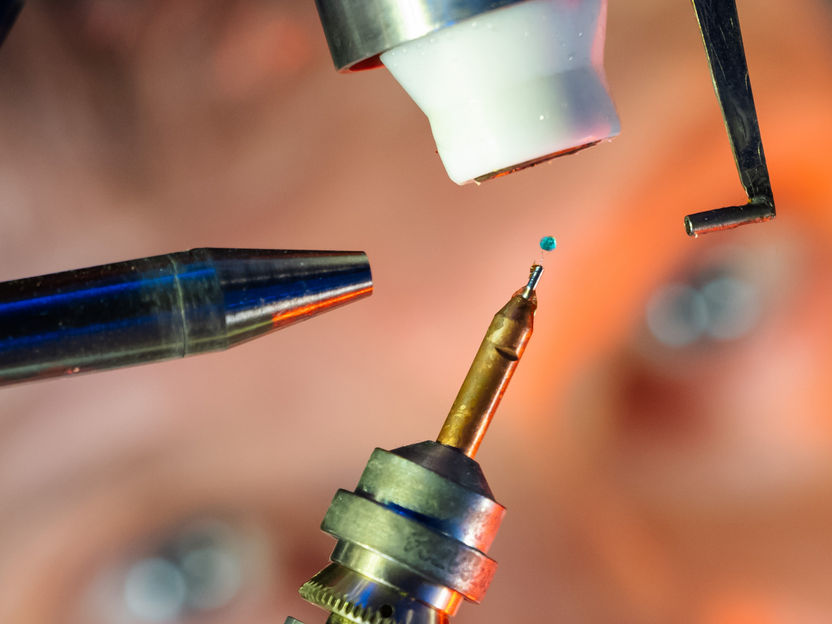

Due to the micrometer/sub-micrometer dimensions of the nanorod forests (dense packing, rod diameters typically few hundreds of nm and lengths < 1 μm) ALD has proven to be ideal technique for manufacturing some of the most crucial cell components. To prevent recombination losses in the active photovoltaic layer and thus cell efficiency decrease, a recombination barrier i.e. passivation layer needs to be coated on the rods’ surface. An ultrathin ALD-deposited Al2O3 film serves ideally this purpose, and the gas-phase, surface-controlled and self-limiting nature of the ALD process ensures that even the deepest and narrowest between-the-rods nooks and crannies will be reliably covered with 100 % uniform, conformal and pinhole- and defect-free passivation film. Another central cell component where ALD has shown its indispensability is the transparent conductive oxide (TCO) layer that works as the current collector on the top of the cell. Different TCO deposition methods were investigated in the course of the project, and ALD turned out to be the ideal method regarding both the TCO film quality and the scalability of the technique, due to Picosun’s fast, efficient and easy-to-use HVM (High Volume Manufacturing) batch ALD system, which was developed specifically during the project ROD-SOL.

Most read news

Organizations

Other news from the department research and development

Get the chemical industry in your inbox

By submitting this form you agree that LUMITOS AG will send you the newsletter(s) selected above by email. Your data will not be passed on to third parties. Your data will be stored and processed in accordance with our data protection regulations. LUMITOS may contact you by email for the purpose of advertising or market and opinion surveys. You can revoke your consent at any time without giving reasons to LUMITOS AG, Ernst-Augustin-Str. 2, 12489 Berlin, Germany or by e-mail at revoke@lumitos.com with effect for the future. In addition, each email contains a link to unsubscribe from the corresponding newsletter.

Most read news

More news from our other portals

Last viewed contents

A Molecule of Light and Matter - Using light, atoms can be made to attract each other

Deepwater Horizon: Identifying harmful elements of persisting oil

Carboxylic_acid

3-D printing and nanotechnology, a mighty alliance to detect toxic liquids

Better batteries inspired by lowly snail shells

Researchers use light to detect Alzheimer's - New technique may help identify ways to predict and prevent deadly disease