GE Betz Facility for Membrane Regeneration Services Opens in Bakersfield

Advertisement

TREVOSE, PA, AUGUST 14, 2002 - GE Betz has opened a facility for regenerating membrane separation elements at its production complex in Bakersfield, California.

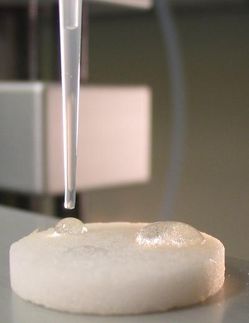

The proprietary process is designed for membrane elements that can no longer be cleaned effectively in the field and would otherwise have to be discarded. It can restore quality performance, extend membrane life and increase the time interval between cleanings at a fraction of the cost of membrane replacement. Permeate flow can be increased, with a corresponding decrease in differential pressure. The off-site cleaning process minimizes system downtime and eliminates chemical purchase, handling and disposal problems.

GE Betz can regenerate spiral wound, thin film, and cellulose acetate reverse osmosis, ultrafiltration and nanofiltration elements from all major suppliers in a full range of sizes.

According to Brian Manerdt, Bakersfield plant manager, the Bakersfield regeneration process has been reengineered to decrease turn-around times and improve restoration effectiveness. "Our closely controlled temperatures and proprietary mechanical features and specialty chemicals can provide superior results compared to the use of clean-in-place equipment at the customer's site."

"This new facility enables us to provide our customers with better service and added value," said George Oliver, GE Betz vice president and general manager.

The Bakersfield manufacturing and distribution facility is ISO 9002 certified and supplies the full line of GE Betz membrane separation treatment chemicals, including membrane compatible cleaners, biological control products, scale inhibitors, filtration aids, deposit control agents, dechlorinators, coagulants and flocculants. GE Betz also offers a diagnostic software program to help reverse osmosis users with the correct selection and dosage of antiscalants and cleaners.

Most read news

Other news from the department research and development

These products might interest you

Get the chemical industry in your inbox

By submitting this form you agree that LUMITOS AG will send you the newsletter(s) selected above by email. Your data will not be passed on to third parties. Your data will be stored and processed in accordance with our data protection regulations. LUMITOS may contact you by email for the purpose of advertising or market and opinion surveys. You can revoke your consent at any time without giving reasons to LUMITOS AG, Ernst-Augustin-Str. 2, 12489 Berlin, Germany or by e-mail at revoke@lumitos.com with effect for the future. In addition, each email contains a link to unsubscribe from the corresponding newsletter.