1,000,000 tonnes of BASF's Trilon complexing agent

A few days ago BASF's Ludwigshafen works produced the millionth tonne of the complexing agent that it markets worldwide under the brand name Trilon®. Brought on stream in 1971, the Trilon plant produces both liquid and powder grades. Growth until the 1980s was modest, but since then demand for complexing agents has risen from year to year. The recently extended plant is running to capacity and making a valuable contribution to BASF's C1 value-added chain. Complexing agents are used to bind troublesome metal ions, which can cause deposits or discoloration. The main fields of application of BASF's Trilon grades are the detergent and cleaning agent industry and the pulp and paper industry, but they are also used in the leather, textile and photographic industries, in electroplating, and in the desulfurization of gases.

Trilon's diverse uses are also valued by end-users. It stops unattractive deposits from forming on holiday photos during development, prevents discoloration and undesirable odours when added as a stabilizer to cosmetic products, makes vehicles sparkle after the car wash without lime stains, and does not give lime a chance in dishwashers or washing machines either.

The Trilon plant is a prime example of how the Verbund works at BASF's Ludwigshafen site. It is a significant part of its C1 chemistry, whose main products are formic acid, formamide and complexing agents. The plant is supplied directly through pipelines from other BASF plants. Its waste products in turn serve neighbouring production plants as valuable raw materials. No residues are produced apart from waste water. Conveying materials via pipelines within the works is cost-efficient and eco-friendly. The products conveyed in the greatest volumes are NTA and EDTA. NTA was first synthesized in the laboratory in 1861 and, like EDTA, has been produced at Ludwigshafen since 1936.

Organizations

Other news from the department research and development

Get the chemical industry in your inbox

By submitting this form you agree that LUMITOS AG will send you the newsletter(s) selected above by email. Your data will not be passed on to third parties. Your data will be stored and processed in accordance with our data protection regulations. LUMITOS may contact you by email for the purpose of advertising or market and opinion surveys. You can revoke your consent at any time without giving reasons to LUMITOS AG, Ernst-Augustin-Str. 2, 12489 Berlin, Germany or by e-mail at revoke@lumitos.com with effect for the future. In addition, each email contains a link to unsubscribe from the corresponding newsletter.

Most read news

More news from our other portals

Last viewed contents

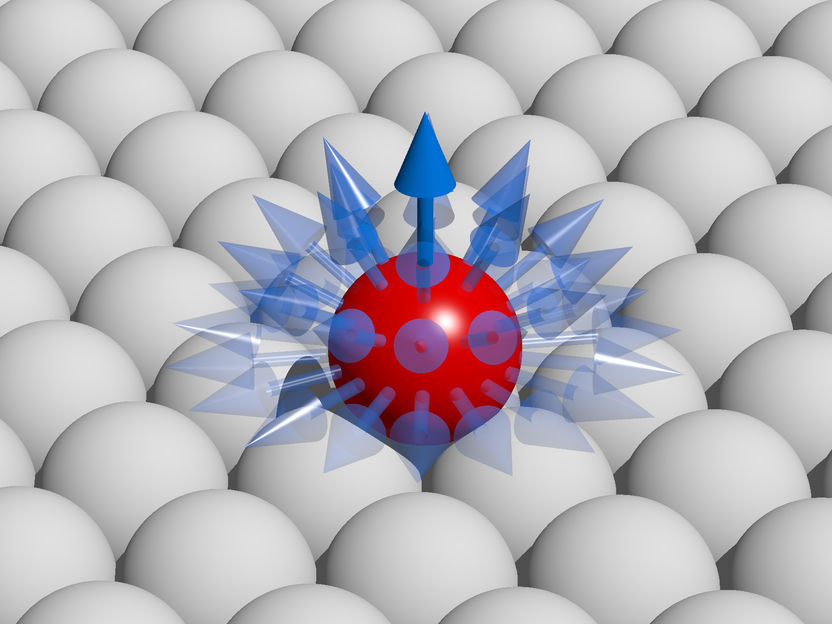

Atomic Bits Despite Zero-Point Energy? - Scientists explore novel ways of developing stable nanomagnets

TSI Acquires Adams Instruments and Facility Monitoring Systems Ltd.

Making waves for ultrahigh definition displays

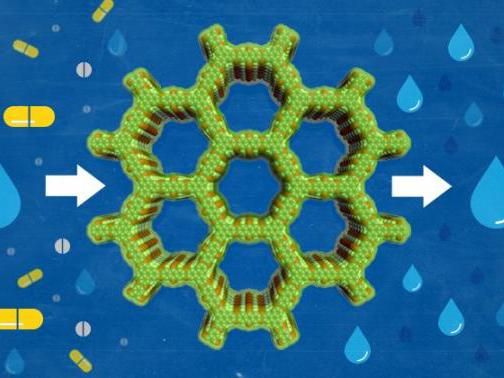

Creating new molecular sieves - Researchers make organic frameworks that could sift antibiotic residue out of water

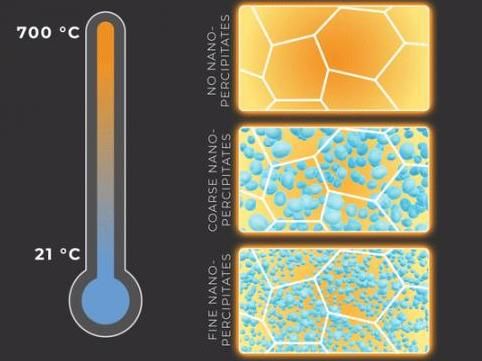

Tiny but mighty precipitates toughen a structural alloy - Scientists have found a way to simultaneously increase the strength and ductility of an alloy

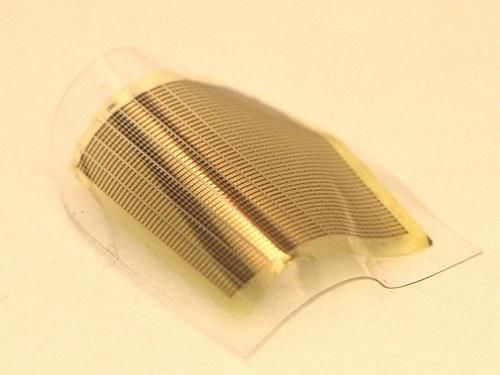

New lightweight shape-shifting alloy shows potential for a variety of applications

Category:Scattering