Intricate, curving 3D nanostructures for biological and materials applications

Twisting spires, rings within rings, and gracefully bending petals are a few of the new three-dimensional shapes that University of Michigan engineers can grow from carbon nanotubes using a unique fabrication method.

Such nanostructured shapes, which are difficult if not impossible to build using conventional techniques, could potentially be used to study cell growth and tissue engineering, the researchers say. They could also lead to new materials with a custom patchwork of surface textures and properties that control condensation or repel dirt, for example.

A paper on the research is published in the October edition of Advanced Materials.

“It’s easy to make carbon nanotubes straight and vertical like buildings,” said A. John Hart, an assistant professor in the Department of Mechanical Engineering and in the School of Art & Design. “It hasn’t been possible to make some of these curved structures.”

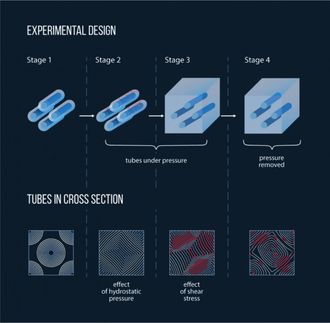

Hart’s method starts by stamping patterns on a silicon wafer. His ink in this case is the iron catalyst that facilitates the vertical growth of the carbon nanotubes in the patterned shapes. Rather than stamp a traditional, uniform grid of circles, Hart stamp hollow circles, half circles and circles with smaller ones cut from their centers. The shapes are arranged in different orientations and groupings. One such grouping is a pentagon of half circles with their flat sides facing outward.

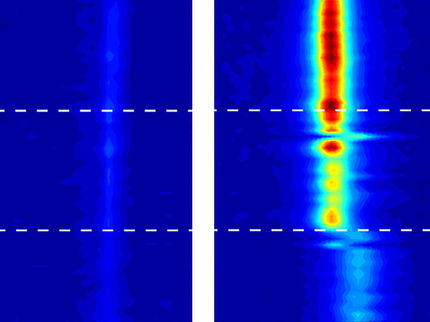

He uses the traditional “chemical vapor deposition” process to grow the nanotubes in the prescribed patterns. Then he suspends the silicon wafer with its nanotube forest over a beaker of boiling solvent, such as acetone. And he lets the acetone condense on the filaments.

When the liquid condenses, capillary action forces kick in and turn these filaments into the intricate curving structures. Capillary action is how liquids can defy gravity if given a thin enough straw to climb. In the pentagon of half circles, the tall half-cylinder filaments bend backwards to form a shape resembling a three dimensional flower.

“We program the formation of 3D shapes with these 2D patterns,” Hart said. “We’ve discovered that the starting shape influences how the capillary forces change the structures’ geometry. Some bend, others twist, and we can combine them any way we want.”

This process allows the researchers to create large batches of free form shapes, all smaller than a cubic millimeter.

“The technology lets us make different shapes at the same time,” Hart said. “We’d like to think this opens up the idea of custom nanostructured surfaces and custom materials with locally varying geometries and properties.”

The paper is called “Diverse 3D Microarchitectures Made by Capillary Forming of Carbon Nanotubes.”

This research is funded by the University of Michigan College of Engineering and the U-M Department of Mechanical Engineering, the Belgium Fund for Scientific Research --- Flanders, and the National Science Foundation.

The university is pursuing patent protection for the intellectual property, and is seeking commercialization partners to help bring the technology to market.

Topics

Organizations

Other news from the department research and development

Get the chemical industry in your inbox

By submitting this form you agree that LUMITOS AG will send you the newsletter(s) selected above by email. Your data will not be passed on to third parties. Your data will be stored and processed in accordance with our data protection regulations. LUMITOS may contact you by email for the purpose of advertising or market and opinion surveys. You can revoke your consent at any time without giving reasons to LUMITOS AG, Ernst-Augustin-Str. 2, 12489 Berlin, Germany or by e-mail at revoke@lumitos.com with effect for the future. In addition, each email contains a link to unsubscribe from the corresponding newsletter.

Most read news

More news from our other portals

Last viewed contents

Measurement method for determining concentrations in dust deposition

Lipoxygenase

Atmospheric Measuring Device for Understanding Smog Formation - Quantitative assessment could lead to more effective smog-control strategies