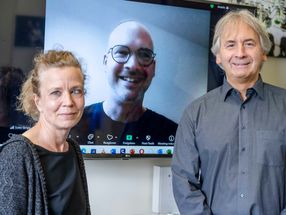

Team of chemists produces biodiesel at their university, using used cooking oil as a basis

The cafeterias at the Catering School on the Leioa campus of the University of the Basque Country (UPV/EHU) use litres upon litres of oil for cooking, given that many students, research workers, lecturers and ancillary staff eat there. Currently a truck takes away all the waste. However, a number of chemistry Faculty lecturers have demonstrated that this oil can be used and revalued at the university itself, having managed to produce biodiesel from the used oil. According to lecturer Ms Eneritz Anakabe, "we have shown that it can be done on a small scale, that biodiesel can be obtained from this oil in a simple manner".

This initiative involves three lecturers in Chemistry from the UPV/EHU, one from the School of Engineers in Bilbao and a number of collaborators. Their research project is called Transesterification. Biodiesels, is financed by the UNESCO Catedra for the Sustainable Development and Environmental Education of the UPV/EHU, and is to last for two years – until 2011. Obviously, to produce large quantities of biodiesel, another type of installation will be required, but what can be produced in the laboratories of the Faculty of Science and Technology is sufficient for the lawn mowers, heating and official cars of the UPV/EHU.

Without greenhouse effect

In order to obtain biodiesel from oil, a transesterification reaction is necessary. The lecturers mentioned have gathered together the literature on various experimental techniques that enable this reaction and have carried out trials until they found the cheapest, most rapid and, in their view, the most appropriate. Not more than an hour is needed to undertake this transformation. Moreover, they have compared their results with commercial biodiesel fuels (taking advantage of the fact that their properties and quantities are known), showing that the product created can be used at the university.

Mr Fernando Mijangos, the person in charge of the project, highlighting the advantages of biodiesel and thereby the product they obtained, compared to diesel fuel, stated, "From the perspective of gases emitted due to the greenhouse effect, these —the biodiesel fuels— are much more profitable than the others and are much cleaner. Diesels are fossil fuels and so induce the greenhouse effect. These fried oils, on the other hand, do not". What is more, if the technique with which they have experimented were to be implemented throughout the university, it would not only result in a zero greenhouse effect, but would also "clean up" the environment: "Instead of dumping the waste down the sink, we offer a cleaner solution. This is its greatest advantage".

Container for oil waste collection

In the months remaining until the project terminates, this group of chemists will focus mainly on two aspects: on the one hand, the optimisation of the product obtained and, on the other, social awareness. As regards the latter, according to Mr Mijangos, the data show that only 3 in every 10 times oil is recycled. The willingness of members of the public, clearly, is indispensable for the raw material collected to be sufficient in order to obtain biodiesel therefrom. The university teachers have taken measures to make the students aware, as Ms Anakabe explains: "We made contact with the Rafrinor company and we placed a container at the entrance —on the right side— of the faculty, in order to collect used oil". It was installed at the beginning of May and will remain there for several months, in order to measure and foment the involvement of the public.

Making people aware is an arduous task. As an example of this, Ms Anakabe refers to her students: "I have 40 students but, to be honest, only ten have committed themselves. This is significant. While the students are more aware, they are still slow in changing – it is "easier" to throw away the oil directly down the sink". Because of this and in order to motivate the students, Mr Mijangos explained that they are undertaking the transesterification reaction —from which we get the biodiesel— jointly with the students. "We are doing two experiments daily, and we are also learning in this way. Moreover, when we finish the project, we hope to write a small booklet with all the experiments and techniques carried out. And then implement them with our students".

Support of UPV/EHU fundamental

In any case, as Mr Mijangos reminds us, "we as researchers are not going to solve this unless there is a commitment from government bodies". Ms Anakabe adds that putting into practice the fruit of these two years of work is in the hands of the people working in the vice-chancellor's office", because government support is essential. "We are scientists and we will continue with our experiments. For example, we will study the treatment to be undertaken (viscosity, density and so on). All this is easy for us. What is not so easy is getting it right in transferring this from laboratory to society", stated Mr Mijangos.