Lanxess: New pre-filter units for the production of iron oxide pigments in Krefeld-Uerdingen

Investment of around EUR 3 million

Advertisement

LANXESS’ Inorganic Pigments business unit is in the process of equipping the Bayferrox iron oxide color pigment production plant at its Krefeld-Uerdingen site with new pre-filter units. Apart from optimizing the safety of the plant, this will also enhance internal logistics processes, thereby improving the reliability of supply. It will also lower energy consumption. "The modernization is part of the worldwide project we are currently implementing at all our production sites to optimize processes, enhance efficiency and improve logistics procedures,” says Jörg Hellwig, head of the business unit, adding: “The aim is to meet constantly mounting customer demand around the world as effectively as possible." The capital expenditures in Krefeld-Uerdingen will total around EUR 3 million. Start-up of the new units is now.

The pre-filter units comprise two stainless steel tanks with peripherals connected to them. They take up the liquid color pigments from the synthesis reactors, which operate in batchwise mode. The pigments are then separated off in the filter units, washed to remove the salt, dried, mixed, ground and packaged. The new pre-filters raise the throughput to the filter units, permitting more efficient supply to the downstream dryers. "This simplifies product flow and ensures better control,” says Franz Mory, the engineer in the project team responsible for the modernization work. “It makes us more flexible in terms of order management and means that we can supply our customers more reliably. The newly installed pumps also lower electricity consumption by around five percent," he adds.

Other news from the department manufacturing

These products might interest you

Most read news

More news from our other portals

See the theme worlds for related content

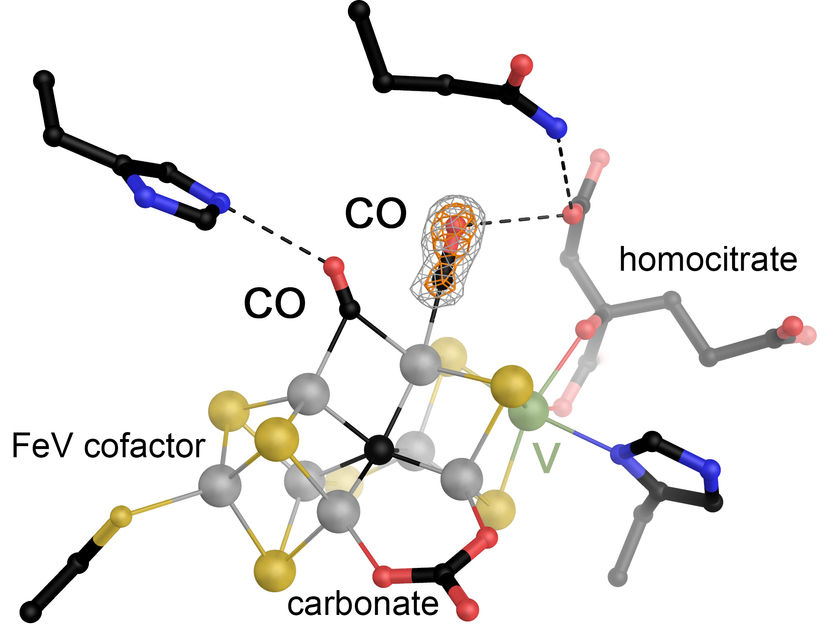

Topic world Synthesis

Chemical synthesis is at the heart of modern chemistry and enables the targeted production of molecules with specific properties. By combining starting materials in defined reaction conditions, chemists can create a wide range of compounds, from simple molecules to complex active ingredients.

Topic world Synthesis

Chemical synthesis is at the heart of modern chemistry and enables the targeted production of molecules with specific properties. By combining starting materials in defined reaction conditions, chemists can create a wide range of compounds, from simple molecules to complex active ingredients.