Turbo test for chemical catalysts

Prof. Ferdi Schüth (MPI für Kohlenforschung, Mülheim), Dr. Dirk Demuth and Dr. Wolfram Stichert (hte AG, Heidelberg) have been nominated for the award “Deutscher Zukunftspreis“

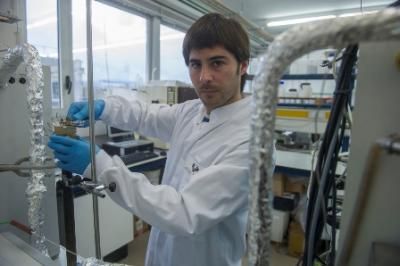

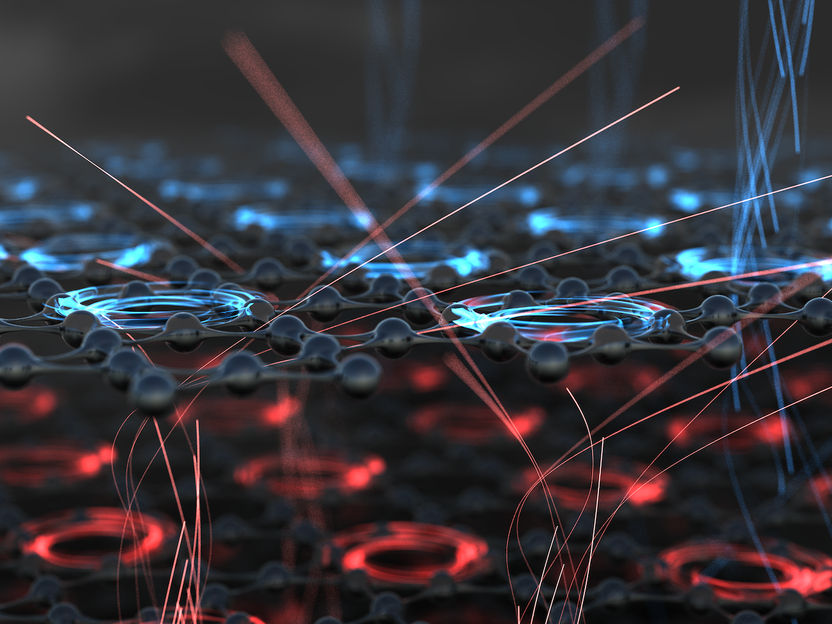

Thanks to a process developed by Prof. Dr. Ferdi Schüth, Director at the Max-Planck-Institut für Kohlenforschung in Mülheim (Germany), and the scientists and technologists of hte Aktiengesellschaft in Heidelberg (Germany) headed by Dr. Dirk Demuth and Dr. Wolfram Stichert, the search for new and more effective catalysts can now be carried out up to 100 times faster than was possible just a few years ago. For their invention the scientists have been nominated for the “Deutscher Zukunftspreis”, the German President’s prize for technology and innovation. They are one of three teams that have made it into the final round of the competition. As reagents which accelerate chemical reactions, catalysts help to save energy, extract more useful products from fossil raw materials and enable the commercial viability of new energy sources, such as hydrogen and fuels based on wood waste.

“The initial response was extremely skeptical. People doubted whether our high throughput system could produce results that would be usable on an industrial scale,” says Prof. Ferdi Schüth, Director of the Max-Planck-Institut für Kohlenforschung and originator of the idea for the turbo test. Although the pharmaceuticals industry has been producing medically active substances for new drugs based on this principle for some time now, many doubted that the method could also work under the considerably harsher conditions encountered in oil refineries and in the production of chemical raw materials.

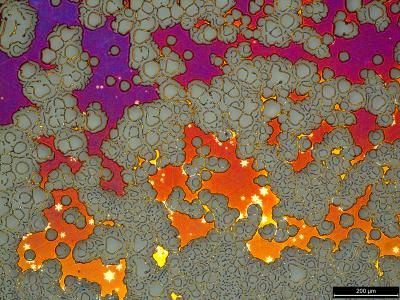

“Today, almost all the petrochemical companies that use our technology are looking for tailor-made catalysts,” explains Dirk Demuth, Chief Executing Officer of hte AG, in which BASF has held a majority shareholding since 2008. The method developed by the nominated scientists and the hte team, which is based on a parallel and automated approach, enables the simultaneous chemical testing of over 100 catalysts. This makes the search for new and more efficient catalysts between ten and 100 times faster than before. The invention represents a major asset for the chemicals industry, as almost all of its products are created with the help of catalysts.

This test process has proven successful not only for applications in the petrochemicals sector, but also in numerous other areas: for example, for testing catalysts needed to transform biomass like wood and straw into fuel, catalysts that can convert chemical raw materials and catalysts that manage with smaller volumes of costly platinum in the conversion of automobile exhaust gases. Materials for more powerful batteries that provide electricity for electric cars can also be identified using this technology.

Other news from the department research and development

Most read news

More news from our other portals

See the theme worlds for related content

Topic World Battery Technology

The topic world Battery Technology combines relevant knowledge in a unique way. Here you will find everything about suppliers and their products, webinars, white papers, catalogs and brochures.

Topic World Battery Technology

The topic world Battery Technology combines relevant knowledge in a unique way. Here you will find everything about suppliers and their products, webinars, white papers, catalogs and brochures.