Cold atoms image microwave fields

Advertisement

microwaves are an essential part of modern communication technology. Mobile phones and laptops, for example, are equipped with integrated microwave circuits for wireless communication. Sophisticated techniques for measurement and characterization of microwave fields are an essential tool for the development of such circuits. A novel technique developed by a group of scientists around Prof. Theodor W. Hänsch (Max Planck Institute of Quantum optics and Ludwig-Maximilians-Universität Munich (LMU)) and Prof. Philipp Treutlein (University of Basel) allows for the direct and complete imaging of microwave magnetic fields with high spatial resolution. In this technique, clouds of ultracold atoms serve as sensors for the microwave field.

Modern wireless communication is based on the transmission of information through radio waves and microwaves. Integrated microwave circuits in devices such as mobile phones and computer laptops decode and process this information. Computer simulations play an important role in the development of these circuits. However, because of the large number of components in modern integrated circuits, such simulations have to rely on approximations and are not always reliable. Therefore, measurements are required to test the circuits and to verify their performance.

To enable efficient testing and specific improvement, one would ideally like to measure all components of the microwave field directly and with very high spatial resolution. In existing techniques for measuring microwave fields, the field distribution has to be scanned point-by-point, so that this kind of data acquisition is slow. Moreover, most techniques only allow for a measurement of the amplitudes, but not of the phases of the microwave field. Furthermore, macroscopic probe heads used for the measurement can distort the microwave field and result in poor spatial resolution.

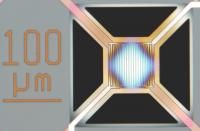

Scientists at the Max Planck Institute of Quantum Optics, the LMU Munich and the University of Basel have now demonstrated a new technique for the imaging of microwave magnetic fields. As microwave field sensors, they use small clouds of ultracold atoms that hade been laser-cooled to a temperature of a few millionths of a degree above absolute zero. At these temperatures, the atoms obey the laws of quantum physics. Their quantum state is very sensitive to externally applied electromagnetic fields, which makes them ideal sensors. For the measurement, the atoms are positioned at the desired location above the microwave circuit with the help of static magnetic fields, and subsequently the microwave field is turned on.

„The internal state of the atoms changes if a microwave field is applied“, Pascal Böhi explains, who co-developed the technique as part of this doctoral thesis. „We can image this change of internal state with a CCD camera with high spatial resolution. The stronger the microwave field at a given position, the faster the rate of change we observe.” A unique feature of the new method is that it does not require the microwave field to be scanned point-by-point. Rather, a fully two-dimensional image of one component of the microwave field can be recorded in a single shot. This increases the data acquisition rate dramatically. In addition, the technique allows not only for a reconstruction of the amplitudes, but also of the phases of the microwave field components. As the atoms are truly microscopic objects, they do not distort the microwave circuit to be characterized, in contrast to macroscopic probe heads. The new method works for various frequencies in the gigahertz range.

„We have successfully demonstrated the new technique in our lab. Quite naturally, further development is necessary before it could be used in commercial applications“, says Philipp Treutlein, the leader of the project. However, a very compact and portable setup for experiments with ultracold atoms was recently built and could be of interest for such applications. The setup itself is at room temperature, but the atoms trapped inside are cooled within a few seconds with the help of laser light. Key components of such systems are now commercially available. Because of the potential for applications, the researchers have submitted a patent application describing the new technique. Philipp Treutlein

Original publication: Pascal Böhi, Max F. Riedel, Theodor W. Hänsch, and Philipp Treutlein; "Imaging of microwave fields using ultracold atoms"; Applied Physics Letters 97, (2010)

Other news from the department science

These products might interest you

Most read news

More news from our other portals

See the theme worlds for related content

Topic world Sensor technology

Sensor technology has revolutionized the chemical industry by providing accurate, timely and reliable data across a wide range of processes. From monitoring critical parameters in production lines to early detection of potential malfunctions or hazards, sensors are the silent sentinels that ensure quality, efficiency and safety.

Topic world Sensor technology

Sensor technology has revolutionized the chemical industry by providing accurate, timely and reliable data across a wide range of processes. From monitoring critical parameters in production lines to early detection of potential malfunctions or hazards, sensors are the silent sentinels that ensure quality, efficiency and safety.