Purple light means go, ultraviolet light means stop

Unique light-controlled membrane acts like a traffic signal for gas

A new membrane developed at the University of Rochester's Laboratory for Laser Energetics blocks gas from flowing through it when one color of light is shined on its surface, and permits gas to flow through when another color of light is used. It is the first time that scientists have developed a membrane that can be controlled in this way by light.

Eric Glowacki, a graduate student at the University's Laboratory for Laser Energetics, and Kenneth Marshall, his advisor, invented the membrane.

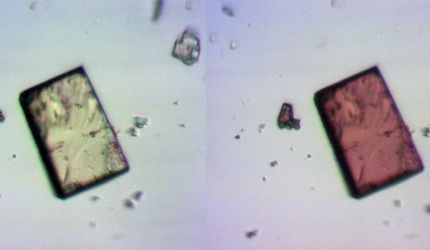

The membrane is a piece of hard plastic riddled with tiny holes that are filled with liquid crystals and a dye. When purple light illuminates the surface of the membrane, the dye molecules straighten out and the liquid crystals fall into line, which allows gas to easily flow through the holes. But when ultraviolet light illuminates the surface, the dye molecules bend into a banana shape and the liquid crystals scatter into random orientations, clogging the tunnel and blocking gas from penetrating.

Controlling a membrane's permeability with light is preferable to controlling it with heat or electricity – two readily used alternative methods – for several reasons, Glowacki said. For starters, light can operate remotely. Instead of attaching electrical lines to the membrane, a lamp or a laser can be directed at the membrane from a distance. This could allow engineers to make much smaller, simpler setups.

Another advantage is that the color of the light illuminating the membrane can be changed precisely and almost instantaneously. Other methods, like heating and cooling, take a relatively long time and repeated heating and cooling can damage the membrane.

Also, light does not have the potential to ignite a gas, which could be a crucial benefit when working with hydrocarbons or other flammable gases. Lastly, the amount of light energy needed to switch the membrane on and off is miniscule.

Creating the membrane is a multi-step process. First, a circular hard plastic chip is bombarded with a beam of neutrons to make the tiny, evenly spaced holes that are about one-hundredth of a millimeter in diameter. The chip is then dipped in a solution of liquid crystals and dye, and the mixture fills the holes through capillary action. The final product is spun in a centrifuge to remove the excess liquid crystals from the surface.

The membrane could be useful in controlled drug delivery and industrial processing tasks that require the ability to turn the flow of gas on and off as well as in research applications.

Topics

Organizations

Other news from the department science

Get the chemical industry in your inbox

By submitting this form you agree that LUMITOS AG will send you the newsletter(s) selected above by email. Your data will not be passed on to third parties. Your data will be stored and processed in accordance with our data protection regulations. LUMITOS may contact you by email for the purpose of advertising or market and opinion surveys. You can revoke your consent at any time without giving reasons to LUMITOS AG, Ernst-Augustin-Str. 2, 12489 Berlin, Germany or by e-mail at revoke@lumitos.com with effect for the future. In addition, each email contains a link to unsubscribe from the corresponding newsletter.

Most read news

More news from our other portals

Last viewed contents

LANXESS: New rubber production line opens in Dormagen

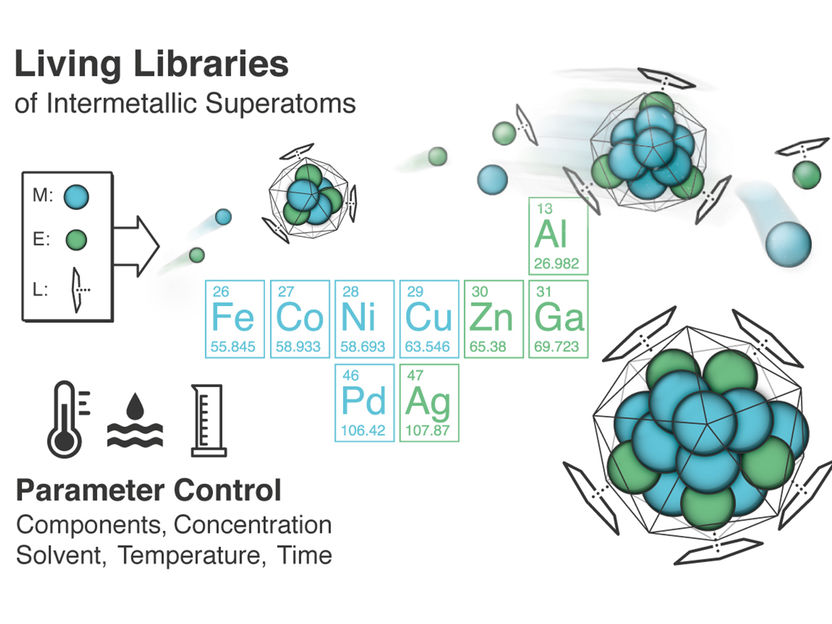

Superatoms as catalysts - Prof. Roland Fischer awarded Reinhard Koselleck Project funding from the DFG

LGC and CIA take major step to establish REACH Centre - LGC and CIA announce joint initiative to help chemical companies implement REACH regulations

Merquinsa appoints Zylog Plastalloys to distribute in India its TPU specialty elastomers product ranges

NOVA Chemicals and GRUPO IDESA to Form Styrenic Polymers Joint Venture in Mexico

Dr. Stefan Beckmann is the new head of Care Chemicals and Formulators Europe at BASF