CCNY-led team develops non-toxic oil recovery agent

Could have applications to Gulf of Mexico spill

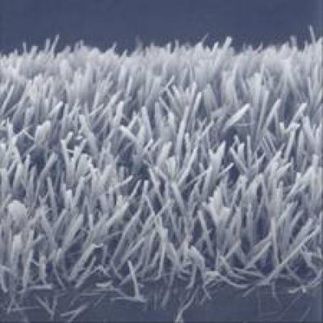

A team of chemists led by Dr. George John, Associate Professor at The City College of New York (CCNY), have developed a non-toxic, recyclable agent that can solidify oil on salt water so that it can be scooped up like the fat that forms on the top of a pot of chilled chicken soup. The agent could potentially be used to recover oil lost in the British Petroleum (BP) spill in the Gulf of Mexico, Professor John said.

In the laboratory, Professor John and colleagues added a sugar compound mixed in alcohol to diesel oil floating on top of a saline solution. "Within five minutes, the oil had gelled into a substance thick enough to be scooped up," he said. Then the team separated 80 percent of the oil from the gel using a vacuum distillation process.

The gelling agent developed by his team is environmentally benign. It uses a sugar-based molecule that can be obtained from renewable sources and is biodegradable. In addition, only a relatively small amount of the agent – five percent of the volume of the oil being recovered – is required for the process, which handles a range of oil from crude to vegetable oil, to work.

The BP oil spill, which began April 24, has been pouring oil into the Gulf of Mexico at the rate of 40,000 barrels per day. Current clean-up methods, which have been in use for more than 40 years, include burning, skimming oil and using chemical dispersants. The latter can be toxic to marine life and may have unknown long-term cumulative effects on the environment, Professor John pointed out.

Other news from the department science

Get the chemical industry in your inbox

By submitting this form you agree that LUMITOS AG will send you the newsletter(s) selected above by email. Your data will not be passed on to third parties. Your data will be stored and processed in accordance with our data protection regulations. LUMITOS may contact you by email for the purpose of advertising or market and opinion surveys. You can revoke your consent at any time without giving reasons to LUMITOS AG, Ernst-Augustin-Str. 2, 12489 Berlin, Germany or by e-mail at revoke@lumitos.com with effect for the future. In addition, each email contains a link to unsubscribe from the corresponding newsletter.

Most read news

More news from our other portals

Last viewed contents

BASF completes sale of Wibarco

BASF starts first MDI production in Chongqing

Method stabilizes, enhances phosphorene

Measurement of Aldehydes and Ketones - Guideline VDI 3862: Gaseous emission measurement

Merger control authorities approve acquisition of Ciba by BASF - Settlement conditions for tender offer fulfilled

David Nicholson to leave Bayer CropScience - Adrian Percy announced as New Head of Research and Development

Michael Siekiera joins management board at Hahnemühle

Desalination with nanoporous graphene membrane