Brilliant counterfeit protection

Counterfeit products create losses in the billions each year. Beside the economic damages, all too often additional risks arise from the poor materials and shoddy workmanship of »knock-off artists«. Yet with the aid of fluorescing dyes, materials can be individually tagged and identified with certainty.

For quite some time now, product piracy has been affecting more than just consumer goods, like watches and designer clothing. The producer industry also has to combat bogus and qualitatively inferior materials. Specialized security features, like watermarks, bar codes, RFID tags and holograms label the products, and thus safeguard them from falsification, theft and manipulation. So when it comes to security features: the more complicated it is to imitate a brand, the more secure the system. A team of researchers from four Fraunhofer Institutes recently engineered a brand new process that is particularly forgery-proof: »We add various fluorescing dyes to the entire material,« explains Dr. Andreas Holländer of the Fraunhofer Institute for Applied Polymer Research IAP. »With the aid of the fluorescence, we can precisely ascertain specific characteristics, and thereby recognize if we are dealing with the original, and if the quality standards have been met.«

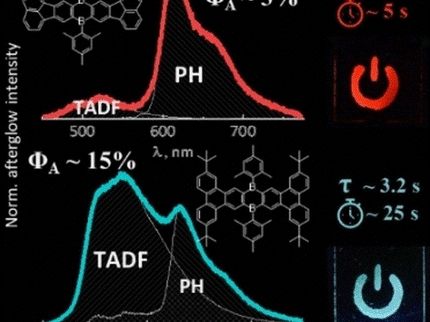

Fluorescence can be found in certain organic dyes: Irradiate them within a certain wave length range, and they emit their own light with a greater wavelength. The type of luminosity – i.e., wavelength and light intensity – depends on the physical and chemical properties of the materials to which the dye was applied. Various dyes react to different properties, such as pH value or viscosity. For example, a certain dye glows in a tightly-interlaced resin more strongly than in one that is not as dense.

To make a product counterfeit-proof, the researchers therefore add multiple dyes to the material. »In this manner, an individualized marker emerges that is exceedingly difficult to imitate,« says Holländer. Thanks to the slight dosing, it is virtually impossible to decode the type and quantity of the dye additives: just a few ppb (parts per billion) of dye concentrates suffice to mark the material. Another advantage: The counterfeit protection definitely cannot be removed. »Using conventional security features, the spot with the labeling can be eliminated from the material, theoretically speaking. But that approach doesn‘t work with our technology, since the dye permeates the entire material, and itself is a component of the identification label,« says Holländer. Beside counterfeit protection, the process is also suitable for an effective quality assurance, such as with coatings: With the aid of various dyes, manufacturers can monitor the chemical composition, degree of dryness and the thickness of the coat during the production process.

The new technology has already passed the first practice tests: Researchers marked barrier sheets for organic light-emitting diodes (OLEDs) and photovoltaics with dyes a development from the Fraunhofer Polymer Surfaces Alliance POLO. The process is basically ready to be used – however, it still must be adapted to each material. A standard solution would also be contrary to the intention of the inventor: »One reason for the high degree of security of our technology is precisely because there are only material-specific solutions,« reiterates Holländer.

Other news from the department science

These products might interest you

OCA 200 by DataPhysics

Using contact angle meter to comprehensively characterise wetting behaviour, solids, and liquids

With its intuitive software and as a modular system, the OCA 200 answers to all customers’ needs

Tailor-made products for specific applications by IPC Process Center

Granulates and pellets - we develop and manufacture the perfect solution for you

Agglomeration of powders, pelletising of powders and fluids, coating with melts and polymers

Dursan by SilcoTek

Innovative coating revolutionizes LC analysis

Stainless steel components with the performance of PEEK - inert, robust and cost-effective

Get the chemical industry in your inbox

By submitting this form you agree that LUMITOS AG will send you the newsletter(s) selected above by email. Your data will not be passed on to third parties. Your data will be stored and processed in accordance with our data protection regulations. LUMITOS may contact you by email for the purpose of advertising or market and opinion surveys. You can revoke your consent at any time without giving reasons to LUMITOS AG, Ernst-Augustin-Str. 2, 12489 Berlin, Germany or by e-mail at revoke@lumitos.com with effect for the future. In addition, each email contains a link to unsubscribe from the corresponding newsletter.