Perovskite solar cells: Thermal stresses are the key to long-term stability

perovskite solar cells are highly efficient and low cost in production. However, they still lack stability over the decades under real weather conditions. An international research collaboration led by Prof. Antonio Abate has now published a perspective on this topic in the journal Nature Reviews Materials. They explored the effects of multiple thermal cycles on microstructures and interactions between different layers of perovskite solar cells. They conclude that thermal stress is the decisive factor in the degradation of metal-halide perovskites. Based on this, they derive the most promising strategies to increase the long-term stability of perovskite solar cells.

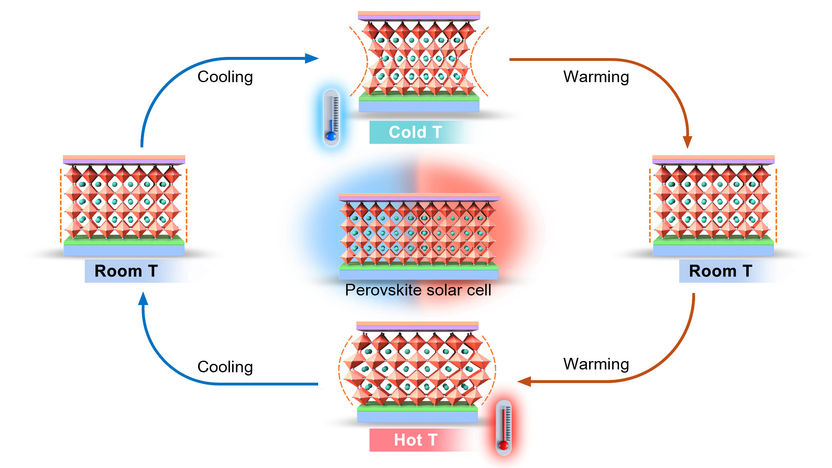

In the experiment, perovskite solar cells were repeatedly cooled to minus 150 degrees Celsius and then heated to plus 150 degrees Celsius. The changes in the microstructure of the perovskite layer and the interactions with the neighbouring layers were studied over the course of the cycles.

Li Guixiang

Perovskites are a wide class of materials with semiconducting properties suitable for energy conversion in a solar cell: the best of them, the metal-halide perovskites, already deliver efficiencies of up to 27%. The production of such thin-film solar cells requires particularly little material and energy, so solar energy could become considerably cheaper. However, when used outdoors, solar modules should provide a nearly stable yield for at least 20 to 30 years. And here, there is still a lot of room for improvement in perovskite materials.

Results from several years

An international research collaboration led by Prof. Antonio Abate has now published the results of several years of work in a review paper in the prestigious journal Nature Reviews Materials. Together with a team led by Prof. Meng Li, Henan University, China, and other partners in Italy, Spain, UK, Switzerland and Germany, they show that thermal stress is the decisive factor in the degradation of metal-halide perovskites.

Harsh conditions in "real life"

‘When used outdoors, solar modules are exposed to the weather and the seasons,’ says Abate. While encapsulation can effectively protect the cells from moisture and atmospheric oxygen, they are still exposed to quite large temperature variations day and night and throughout the year. Depending on the geographical conditions, temperatures inside the solar cells can range from minus 40 degrees Celsius to plus 100 degrees Celsius (in the desert, for example).

Effects of extreme temperature differences studied

To simulate this, the perovskite solar cells in the study were exposed to much more extreme temperature differences in several cycles: From minus 150 degrees Celsius to plus 150 degrees Celsius, and again and again. Dr Guixiang Li (then a postdoc at HZB, now a professor at Southeast University, China) investigated how the microstructure within the perovskite layer changed during the cycles and to what extent the interactions with the neighbouring layers were also affected by the temperature cycles.

Thermal stress inside the perovskite film and in between layers

Together, these factors affect the performance of the cell. In particular, the temperature cycles caused thermal stress, i.e. stress both within the perovskite thin film and between the different adjacent layers: ‘In a perovskite solar cell, layers of very different materials need to be in perfect contact; unfortunately, these materials often have quite different thermal behaviours,’ explains Abate. For example, plastics tend to shrink when heated, while inorganic materials tend to expand. This means that in each cycle the contact between the layers becomes worse. What is more, also local phase transitions and diffusion of elements into adjacent layers have been observed.

Most promising strategy

From this, the research teams have derived a strategy to increase the long-term stability of perovskite solar cells. ‘Thermal stress is the key,’ says Abate. The main thing, therefore, is to make the perovskite structures and the adjacent layers more stable against thermal stress, for example by increasing the crystalline quality, but also by using suitable buffer layers. The scientists highlight the importance of uniform test protocols for evaluating stability under temperature cycling and propose an approach to facilitate comparison between different studies.

Original publication

Luyan Wu, Shuaifeng Hu, Feng Yang, Guixiang Li, Junke Wang, Weiwei Zuo, José J. Jerónimo-Rendon, Silver-Hamill Turren-Cruz, Michele Saba, Michael Saliba, Mohammad Khaja Nazeeruddin, Jorge Pascual, Meng Li, Antonio Abate; "Resilience pathways for halide perovskite photovoltaics under temperature cycling"; Nature Reviews Materials, 2025-2-19

Most read news

Original publication

Luyan Wu, Shuaifeng Hu, Feng Yang, Guixiang Li, Junke Wang, Weiwei Zuo, José J. Jerónimo-Rendon, Silver-Hamill Turren-Cruz, Michele Saba, Michael Saliba, Mohammad Khaja Nazeeruddin, Jorge Pascual, Meng Li, Antonio Abate; "Resilience pathways for halide perovskite photovoltaics under temperature cycling"; Nature Reviews Materials, 2025-2-19

Organizations

Other news from the department science

Get the chemical industry in your inbox

By submitting this form you agree that LUMITOS AG will send you the newsletter(s) selected above by email. Your data will not be passed on to third parties. Your data will be stored and processed in accordance with our data protection regulations. LUMITOS may contact you by email for the purpose of advertising or market and opinion surveys. You can revoke your consent at any time without giving reasons to LUMITOS AG, Ernst-Augustin-Str. 2, 12489 Berlin, Germany or by e-mail at revoke@lumitos.com with effect for the future. In addition, each email contains a link to unsubscribe from the corresponding newsletter.

Most read news

More news from our other portals

Last viewed contents

ALTANA acquires formulated resins business from Solvay - Will be incorporated into the ELANTAS Electrical Insulation division

Evonik sells its US Jayhawk site - Company continues to intensify focus on high-margin specialty chemicals businesses

Solvay projects 35 percent capacity increase of sulfone polymer production over the next five years

Chiral Quest announces opening of new operations facility - In the Princeton/NJ area Chiral Quest intends to enlarge production of catalysts and larger scale chiral phosphines

Covestro continues production at Tarragona site - Investment of around EUR 200 million

Study finds flame retardant exposure higher in infants than adults

Styrolution Group GmbH - Frankfurt am Main, Germany

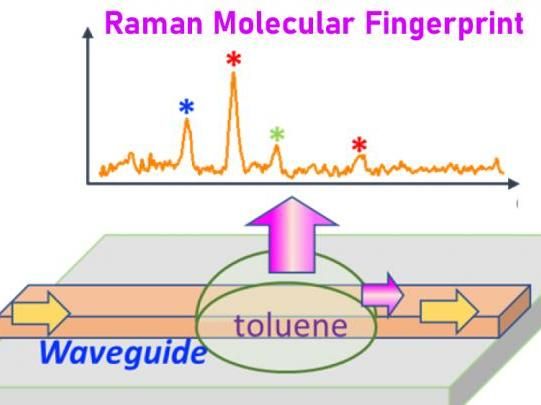

Researchers dramatically downsize technology for fingerprinting drugs and other chemicals - Tiny photonic chip could fit comfortably within the tip of a finger